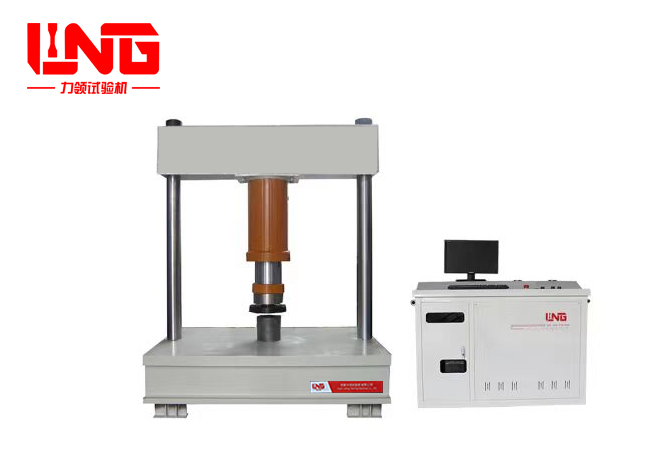

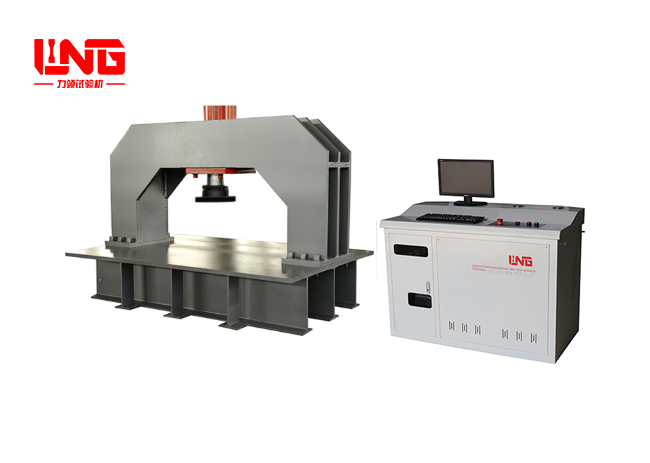

Anti bending and compression integrated machine shipped to Indonesia

Machine Introduction:

The YAW-300C anti bending and anti compression integrated machine is a pressure testing machine that can withstand 30 tons of compression and 1 ton of bending. It is strictly manufactured according to the testing requirements of GB/T17671-1999 cement mortar degree inspection method. It is controlled by a microcomputer and has control modes such as constant velocity test force, constant velocity stress, and dual station test space for maintaining test force. The test data is achieved by computer technology. The test curve has functions such as screen display, disk storage, database management, and can output experimental data reports when connected to a printer. The product has high accuracy, superior performance, high reliability, and easy operation.

The measurement and control system adopts high-precision digital servo valves with force closed-loop control function, which can achieve equal load rate loading or equal stress rate loading. The control accuracy is high, the reliability is good, and it fully meets the requirementsGB/T 17617《 The method for testing the strength of cement mortar (ISOmethod) requires the use of microcomputers to achieve electronic measurement, automatic completion of compressive strength tests, automatic calculation and printing of reports.,is widely used in the construction industry and cement production enterprises.

Hydraulic system:

This machine adopts dual oil cylinders, with high control accuracy and measurement accuracy. The hydraulic oil in the oil tank is driven by a motor to enter the oil circuit through a high-pressure pump, and flows through a one-way valve, a high-pressure oil filter, a differential pressure valve group, and a servo valve before entering the oil cylinder. The computer sends control signals to the servo valve to control the opening and direction of the servo valve, thereby controlling the flow into the oil cylinder and achieving control of the constant velocity test force.

Force measurement system:

l Using high-precision amplifiers and A/D converters, the entire process is not divided into stages, and real-time display of load, peak value, loading speed, and intensity is available;

l Adopting PID closed-loop control strategy to achieve constant speed loading and real-time display of loading curve

l Automatic interval timing and continuous testing;

l Flexible and convenient query and printing of test results;

l Safety protection device:

l When the test force exceeds 3% of the full range, overload protection is activated and the oil pump motor is shut down.

l When the piston rises to the upper limit position, the limit protection stops and the oil pump motor stops.

Foreign customers value the reasonable product design and accurate test results of Liling Company, and have signed a contract for pre payment and shipment to Indonesia!