News (click to select category)

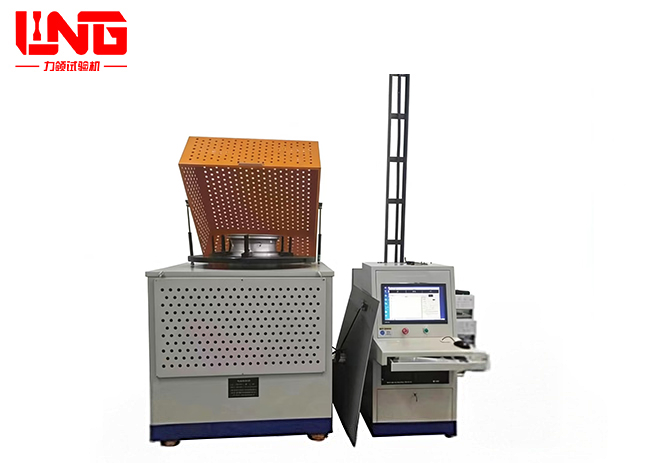

Breaking through technological barriers! Jinan Leading launches wheel rotation bending fatigue testing machine, adding weight to automotive safety

Date:2026-01-21ID: 286Heat:

In today's automotive manufacturing industry, which pursues longer lasting, safer and more reliable performance, the rotational bending fatigue performance of wheels has become a key indicator for measuring the safety of the entire vehicle. The latest wheel rotation bending fatigue testing machine developed by Jinan Liling Testing Machine Co., Ltd. has been officially unveiled. The equipment uses resonance principle technology to increase the testing frequency to 50Hz, greatly reducing the testing cycle.

The core technology of the wheel rotation bending fatigue testing machine launched this time lies in the clever use of resonance principle. The device drives a precision eccentric mass block to rotate and generate centrifugal force through a variable frequency servo motor.

When the rotation frequency approaches the natural frequency of the tested wheel axle system, the small excitation force will be amplified by hundreds of times, thereby achieving efficient and high-frequency fatigue testing with extremely low energy consumption.

Compared with traditional testing equipment, this technological breakthrough enables testing frequencies to reach up to 50Hz, which is several times more efficient than conventional equipment and greatly shortens the product development and validation cycle.

Jinan Leading has been laying out in this field for two years, and the technical experience accumulated in the early stage of electro-hydraulic servo fatigue testing machine has laid a solid foundation for this product innovation

The core technology of the wheel rotation bending fatigue testing machine launched this time lies in the clever use of resonance principle. The device drives a precision eccentric mass block to rotate and generate centrifugal force through a variable frequency servo motor.

When the rotation frequency approaches the natural frequency of the tested wheel axle system, the small excitation force will be amplified by hundreds of times, thereby achieving efficient and high-frequency fatigue testing with extremely low energy consumption.

Compared with traditional testing equipment, this technological breakthrough enables testing frequencies to reach up to 50Hz, which is several times more efficient than conventional equipment and greatly shortens the product development and validation cycle.

Jinan Leading has been laying out in this field for two years, and the technical experience accumulated in the early stage of electro-hydraulic servo fatigue testing machine has laid a solid foundation for this product innovation