How to operate the impact testing machine correctly? Detailed explanation of operation steps and precautions

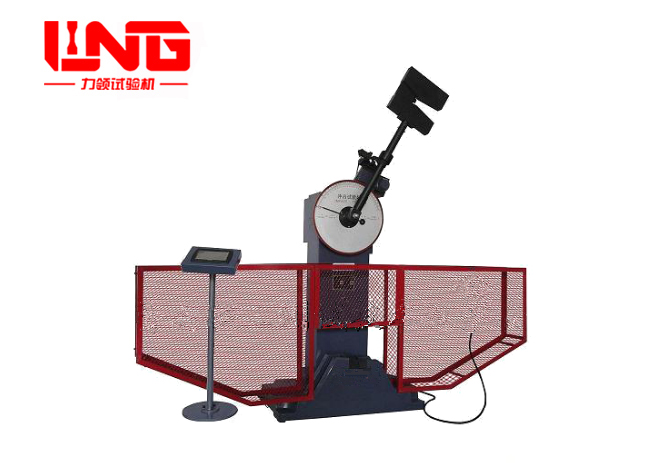

1、 Preparation of impact testing machine

1. Check the equipment of the impact testing machine to ensure that the instrument is not damaged and there are no foreign objects inside.

2. Calibrate instruments, including setting test parameters, calibrating sensors, etc.

3. Prepare the sample, including cutting it and fixing it in the fixture of the impact testing machine.

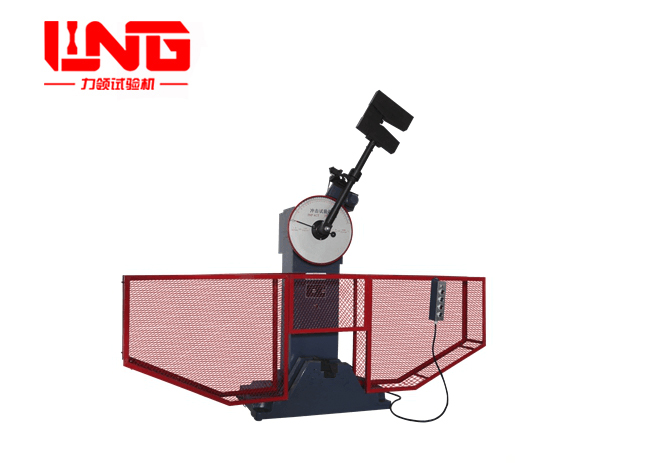

2、 Installation and Handling of Samples

1. Check the sample to ensure it meets the requirements and avoid any unknown issues that may affect the test results.

2. Fix the sample in the fixture of the impact testing machine, and pay attention to the compatibility and tightness between the fixture and the sample.

3. Avoid touching the sample and avoid leaving fingerprints or stains on your fingers.

3、 Setting of experimental parameters

When setting experimental parameters, attention should be paid to the current standards or specifications.

2. Set the test parameters correctly, including the direction of application, test temperature, impact velocity, impact energy, etc.

3. Set factors that affect the test results, including atmospheric pressure, standard fixtures, etc.

4、 Precautions during the experimental process

Before the experiment, it should be checked whether all experimental parameters have been set.

During the testing process, the testing area should be kept clean and other items should be prevented from damaging the testing equipment.

In the experiment, the experimental standards and specifications should be followed to avoid the impact of operational errors on the experimental results.

At the end of the experiment, the fixture and sample should be promptly removed from the impact testing machine.

5、 Frequently Asked Questions and Answers

How should the sample of the impact testing machine be selected

Answer: The sample should take into account the requirements for sample category, shape, size, quantity, etc. in the test standards or specifications.

What could be the possible reason for the abnormal test results

Answer: Abnormal test results may be caused by instrument malfunctions, samples that do not meet requirements, incorrect test parameter settings, improper instrument calibration, and other reasons.

【 Conclusion 】

This article provides a detailed introduction to the operation steps and precautions of the impact testing machine, including instrument preparation, sample installation and processing, setting of test parameters, and precautions during the testing process. When operating the impact testing machine correctly, it is necessary to follow the specifications to avoid the impact of operational errors on the test results.