How to use the high-strength bolt anti slip coefficient tester

Bolts made of high-strength steel or requiring significant pre tightening force can be referred to as high-strength bolts. High strength bolts are commonly used for connecting bridges, steel rails, high-pressure, steel structure buildings, and ultra-high voltage equipment. The fracture of this type of bolt is mostly brittle fracture. High strength bolts applied to ultra-high voltage equipment require significant pre stress to ensure the sealing of the container.

Several concepts of high-strength bolts: 1. According to regulations, bolts with a performance level of 8.8 or above are called high-strength bolts The difference between high-strength bolts and ordinary bolts:

High strength bolts can withstand loads greater than ordinary bolts of the same specification.

The material of ordinary bolts is Q235 (i.e. A3) manufactured. The material of high-strength bolts is 35 # steel or other high-quality materials, which undergo heat treatment after production to improve their strength.

High strength bolts need to be sampled and inspected by the quality inspection department before leaving the factory. Once they are found to be unqualified, they cannot enter the market. In order to ensure the quality of high-strength bolts, various corresponding tests need to be carried out. Different testing equipment corresponds to different technical indices of high-strength bolts. When high-strength bolts are sent to steel structure factories as components, it is necessary to provide test data on the anti slip coefficient of the bolt joint surface tested at the factory. In fact, the test value cannot be less than 0.55. The anti slip coefficient specimens sent together with the components are divided into three groups per batch and transported to the construction site for re inspection and acceptance.

The high-strength bolts used for testing should be made of the same material as the actual high-strength bolts. And it must be products from the same period, batch, and friction surface treatment process. And it needs to be transported and stored under the same conditions.

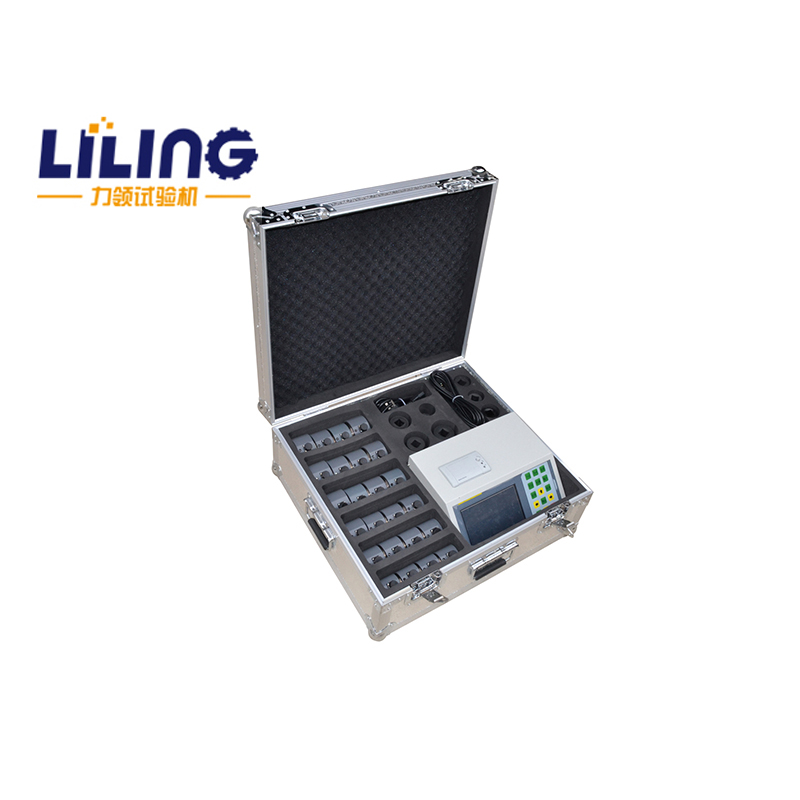

Next, we will mainly talk about the method of conducting anti slip coefficient tests for high-strength bolts during site re inspection and acceptance. This method generally uses pressure sensors to control the pre tension of high-strength bolts. The pre tension value of each high-strength bolt should be between 0.95p and 1.05p, where p is the design pre tension value of the high-strength bolt. The pressure sensor used for testing should be calibrated with a testing machine before the experiment, with an error of only 2%. High strength bolts are subjected to tensile testing on high-strength bolt components using a universal material testing machine until sliding failure occurs, and the sliding load values are obtained from the testing. Calculate the anti slip coefficient. During the re inspection on the construction site, the anti slip coefficient must not be less than 0.45. The detection of slip coefficient requires an anti slip coefficient detector, which is used in conjunction with a universal machine to detect the slip coefficient. Testing high-strength bolts also requires the use of a high-strength bolt tester in conjunction with it!