News (click to select category)

Jinan Leading Testing Machine Mechanical Testing Machine Testing Equipment Debugging Completed Notice

Date:2026-01-26ID: 288Heat:

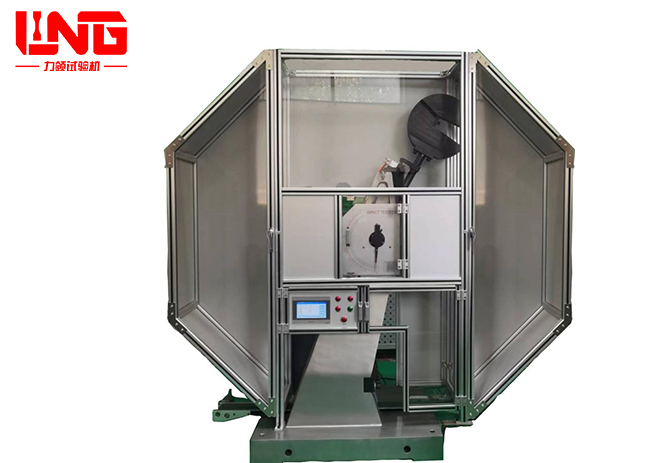

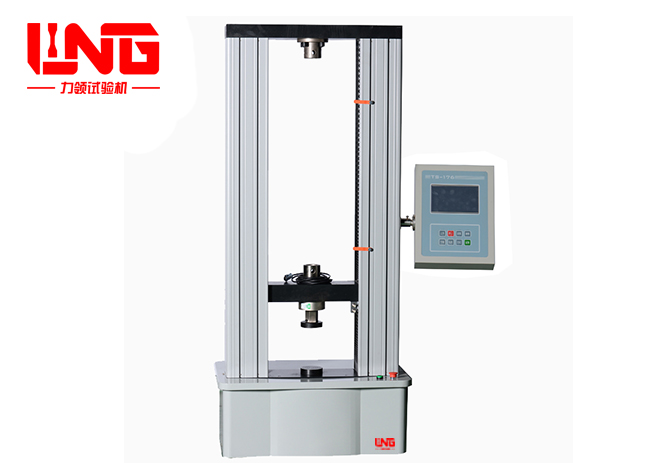

Recently, Jinan Liling Testing Machine Co., Ltd. has completed all the debugging work for the complete set of testing equipment supplied to customers. The debugging equipment includes a 30 ton electronic universal testing machine, a 100 ton universal testing machine, a semi-automatic impact testing machine, an impact sample projector, a lathe and other core products. It comprehensively covers multiple scenarios such as material mechanics testing and sample processing, and can meet the diverse testing needs of different customers such as university laboratories and enterprise quality inspection departments.

During the debugging process, our professional technical team strictly follows relevant national industry standards and equipment operation specifications, and conducts comprehensive verification and debugging of core indicators such as performance parameters, operational stability, and detection accuracy for each device. For key parameters such as loading speed and force accuracy of 30 ton and 100 ton electronic universal testing machines, impact energy and testing efficiency of semi-automatic impact testing machines, imaging clarity of impact sample projectors, and processing accuracy of tensile machines, repeated testing and calibration are carried out one by one to ensure that all equipment indicators are accurately met without any operational hazards.

After all the equipment has been debugged and qualified, the after-sales personnel have completed the equipment operation demonstration and key operation process sorting, ensuring that customers can quickly get started operating the equipment after receiving it. Jinan Leading always adheres to the concept of "quality first, service foremost". The successful commissioning of this equipment is not only a confirmation of our company's product research and development and production strength, but also a sincere feedback to our customers' trust.

During the debugging process, our professional technical team strictly follows relevant national industry standards and equipment operation specifications, and conducts comprehensive verification and debugging of core indicators such as performance parameters, operational stability, and detection accuracy for each device. For key parameters such as loading speed and force accuracy of 30 ton and 100 ton electronic universal testing machines, impact energy and testing efficiency of semi-automatic impact testing machines, imaging clarity of impact sample projectors, and processing accuracy of tensile machines, repeated testing and calibration are carried out one by one to ensure that all equipment indicators are accurately met without any operational hazards.

After all the equipment has been debugged and qualified, the after-sales personnel have completed the equipment operation demonstration and key operation process sorting, ensuring that customers can quickly get started operating the equipment after receiving it. Jinan Leading always adheres to the concept of "quality first, service foremost". The successful commissioning of this equipment is not only a confirmation of our company's product research and development and production strength, but also a sincere feedback to our customers' trust.