Jinan Liling will discuss with you about the impact testing machine

The usage rate of impact testing machines is relatively high, and laboratories generally need more than just impact testing machines. Often requires many supporting products related to it.

The required test material for an impact testing machine is a test block with U-shaped and V-shaped notches. To manufacture this type of machine, manual or electric lathes are needed for assistance. Therefore, for impact testing, an electric or manual lathe is required. Currently, most lathes in the market come with a V-shaped tool, and our Jinan Liling Testing Machine Co., Ltd. manual lathe can also be equipped with both U-shaped and V-shaped tools.

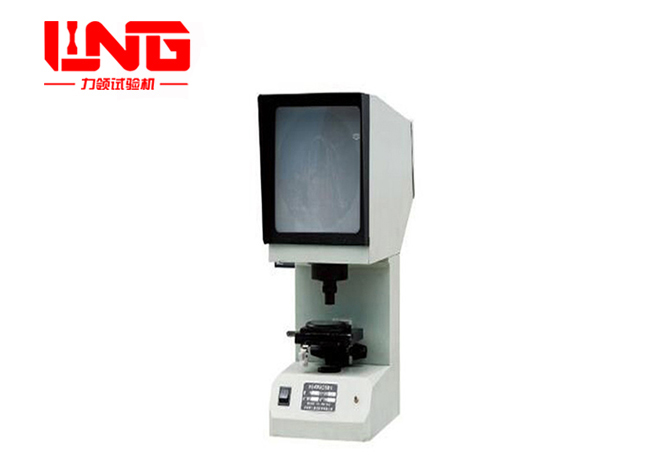

An electric lathe is directly equipped with two cutting tools. In addition to the lathe, after the pattern is prepared, it is necessary to check whether the pattern is made in accordance with industry standards. This requires a projector to assist in magnifying the image of the pattern. Our Jinan Liling Testing Machine Co., Ltd. is equipped with a CST-50, 50x magnification projector.

If a low-temperature test is required, a low-temperature tank needs to be equipped to assist in cooling. Currently, the low-temperature tank can cool down to minus 60 degrees or 80 degrees, and if there are special requirements, liquid nitrogen refrigeration can cool to minus 196 degrees.

The above products related to impact testing, such as impact testing machines, notch pull-out machines, low-temperature tanks, and projectors, are produced by Jinan Liling Testing Machine and available in stock. If you have any demand, please call us for more information.