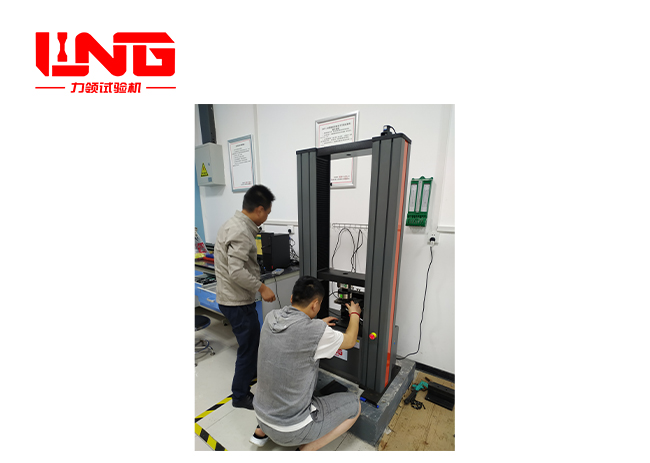

The pedal testing machine is deeply loved by customers and has received recognition and praise from them

1、 Product Overview:

This series of testing machines is independently designed and produced by our company based on testing machine technology. This machine is widely used in industries such as building materials, aerospace, machinery manufacturing, wires and cables, rubber and plastics, textiles, and home appliances to test and analyze the mechanical performance indicators of various metal, non-metal, and composite materials. It is an ideal testing equipment for scientific research institutions, colleges and universities, industrial and mining enterprises, technical supervision, quality inspection and other departments.

This series of testing machines achieves automatic control, data acquisition, and analysis of the testing process through computers, realizing full digitization and automation of the data acquisition, analysis, and control process. The control and data processing software with WINDOWS as the operating interface realizes the computer display of test force, peak test force, beam displacement, test deformation, and test curve. The user-friendly design makes the test operation more convenient. This machine can achieve closed-loop control of test force, deformation, and displacement, and can smoothly switch between control modes such as constant stress, constant strain, and constant displacement. This machine fully meets the corresponding national standard requirements, and can conduct tests and data processing according to GB, ISO, JIS, ASTM, DIN, and multiple standards provided by users, with good scalability.

2、 Product Structure and Function:

This series of testing machines adopts a portal frame structure, with the lower space used as the tension, compression, and bending testing space. Replace different accessories and conduct mechanical performance tests on various metal and non-metal materials such as pipes, plastics, rubber waterproof materials, etc.

1. This series of machines adopts AC servo motors and speed control systems to drive precision ball screw pairs to move up and down, thereby achieving a wide range of stepless adjustment of test speed, ensuring high precision, low noise, and high stability during the test process.

2. The attachment link adopts a universal joint cross pin structure and has a swing angle limiting function. On the one hand, it is convenient for sample clamping, ensuring the concentricity of the test, and on the other hand, it effectively eliminates the influence of irregular samples on the sensor.

3. The experimental control system has the advantages of high integration, stable performance, and easy adjustment. Real time collection of experimental data can be achieved, and real-time dynamic display of experimental characteristic curves can be realized. Experimental data files can be saved in the form of commonly used databases in Access, which facilitates customer resource sharing and network management, as well as user reanalysis. For various user-defined Word2003 reports, this software can easily access them, solving the problem of different users or the same user having different needs for experimental reports at different times. This software can process raw data of experimental force, displacement, time, deformation, and the curves derived from them.

4. Protection function: The machine has two types of limit protection: software and mechanical. The proportion of automatic shutdown beyond the maximum load can be dynamically set; It has multiple protection functions such as overcurrent, overvoltage, overload, etc.

5. For load and deformation channels, automatic labeling can be achieved, which is intuitive and convenient.

6. Batch testing can achieve hierarchical display of curves and automatic curve tracking.

7. This software can achieve user-defined speed settings and computer adjustment of speed. It can also achieve high-precision speed calibration, adjust speed gear and coding at any time.

8. Monitoring the experimental process: Real time display of various parameters such as test force, deformation, displacement, and curve during the experimental process can be achieved.

9. Software permission level management function: In order to improve the security of software and data, this software can achieve permission level management function by setting different password protections.

10. Result reproduction function: After the experimental operation is completed and saved, it can be opened and reanalyzed at any time according to the user's needs.

11. Users can select curves such as load deformation, load time, load displacement, displacement time, and deformation time according to their needs for testing, data display, storage, analysis, and printing.

12. Curve point by point traversal function: You can click on the force and deformation values on the curve with the mouse to obtain various parameters for each point.

13. Force interface: The force channel interface and testing software can be equipped with various sensors according to user needs, and can perform calibration, parameter modification, and normal testing.

14. Deformation interface: The deformation channel interface and testing software can be equipped with various types of extensometers according to user needs, and can perform calibration, parameter modification, and normal testing.

15. The software operation interface is shown in the figure (the software may vary slightly depending on the requirements of different experiments)