Tips for using HY-24L anti slip coefficient tester

Anti slip coefficient tester, mainly used to detect the frictional force generated on the surface of fasteners and the products they fasten, thereby detecting the frictional force between fasteners and friction surface coatings, and further detecting the slip coefficient of materials..

Force collar testing machineAnti slip coefficient detector, using a high-precision and clear panel microcomputer control instrument with dual control and dual display, adopting a dual control mode integrating physical buttons and control screen buttons, with clear display and precise control during use, and strong control feeling during use.

The anti slip coefficient detector adopts 6 sets of 4-channel, 220V power supply, and the overall accuracy of the sensor is better than 1%. It is used in conjunction with the HAW series electro-hydraulic servo universal testing machine with a tonnage of 600 kN or above.

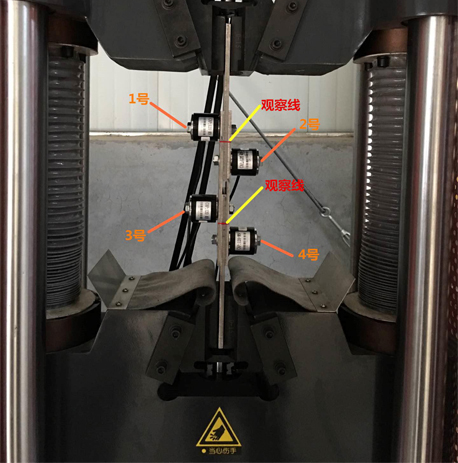

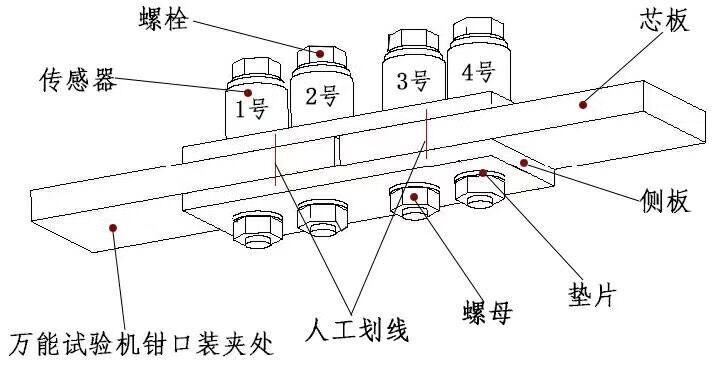

During the use of the anti slip coefficient tester, it is necessary to thread and effectively fasten the four sensors and fastening bolts together. The four slip test core plates should be evenly arranged, with one set of two sensors on the top and one set of two sensors on the bottom. Remember to mark the core plates evenly and place them on the HAW electro-hydraulic servo universal testing machine for stretching. Record the load value of the tensile testing machine that causes the misalignment of the core plate marking, input it into the microcomputer, and the microcomputer will automatically calculate the slip coefficient based on the obtained value.

The fastening of the sliding core plate during use can be achieved using a twisting device, combined with the LJZ series high-strength bolt detector, which is convenient and lightweight to achieve precise pre force application.