What is the difference between microcomputer controlled electronic universal testing machine C-type machine and D-type machine?

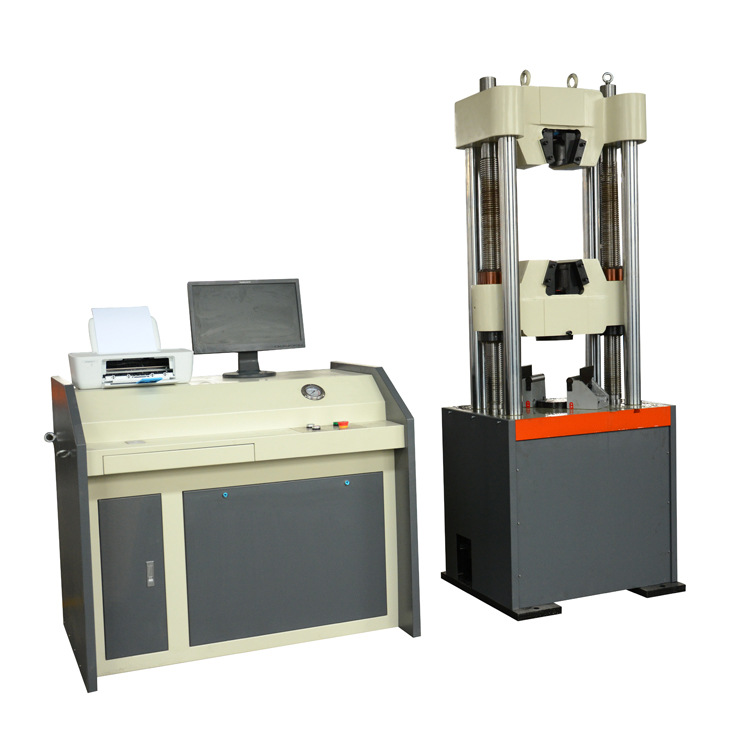

Hydraulic universal testing machineThere are multiple models including digital display hydraulic universal testing machine, screen display hydraulic universal testing machine, and microcomputer controlled electro-hydraulic servo universal testing machine. The microcomputer controlled electro-hydraulic servo universal testing machine includesmicrocomputer controlled electro-hydraulic servo universal testing machine C-type machineand microcomputer controlled electro-hydraulic servo universal testing machine D-type machine. What are the differences between microcomputer controlled electro-hydraulic servo universal testing machine C-type machine and D-type machine?

The microcomputer controlled electro-hydraulic servo universal testing machine C-type machine is equipped with nut rotation, turbine worm drive, and seamless stretching space.

The D-type microcomputer controlled electro-hydraulic servo universal testing machine is equipped with screw rotation, chain transmission, and gap stretching space.

1、 What is a gap stretching space?

All testing machines that use screw rotation to achieve the lifting and lowering of the lower crossbeam have clearance tension space. There must be a gap between the back cap of the screw and the base to ensure that the screw can rotate. For example, the D-type machine.

2、 What is seamless stretching space?

1. In any testing machine where the screw is fixed and the lower crossbeam is lifted and lowered by rotating the nut, a clearance elimination mechanism is assembled between the nut and the screw, and a pre tightening force is applied to overcome the self weight of the lower crossbeam. When the nut rotates, it contacts the upper end face of the screw, eliminating the gap between the screw and the nut. Therefore, it is called a gapless tensile space. For example, the C-type machine.

2. The upper and lower crossbeams of the single pull testing machine are fixed and immovable, and the adjustment of the stretching space is achieved through the lifting and lowering of the piston, which provides no stretching space.

3、 Does the gap stretching space have an impact on the experimental results?

What is the difference between a C-type machine and a D-type machine?

1. It has no effect on the measurement accuracy of the test force. Has an impact on the continuity of the test force curve.

When conducting tensile (or compression) tests on a universal testing machine with clearance stretching space, the first step is to overcome the self weight of the crossbeam and screw, eliminate the gaps between the screw back cap and base, and between the nut and screw. Due to the fact that the direction of gravity is exactly the same as the measurement direction of tension (or pressure), it does not affect the accuracy of the value measurement at all. But in the initial stage of drawing the force time curve, a platform will appear, and the force value of the platform is measured by the self weight of the screw, indicating the discontinuous application of the test force. This situation is allowed in GB/T228.1-2010, and a suggestion for pre tensioning is also proposed.

2. There is no impact on the measurement results of the elongation performance of the sample.

The universal testing machine with shock gap stretching space will not have any impact on the test results of the stretching (or compression) performance when conducting tensile (or compression) tests. Because GB/T228.1-2010 Metallic Materials Room Temperature Tensile Test Method specifies that Ae, Ag, Agt, and At are all measured by extensometers and are independent of displacement; The elongation at break A is calculated based on the measured post break gauge length and is independent of displacement. In the initial stage of drawing the displacement time curve, a platform will appear, and the displacement of the platform is the gap between the screw back cap and the base, and between the nut and the screw.

The C-type machine has finer workmanship and smoother transmission than the D-type machine.

Although the universal testing machine with gap stretching space has no effect on the measurement results of the strength and elongation properties of the material during tensile testing, it still shows that the manufacturing of the testing machine is not precise enough. The initial stages of force time curves and displacement time curves both have a small tail.

Whether the testing machine has a seamless tensile space is one of the important indicators of high-quality testing machines and should not be underestimated.