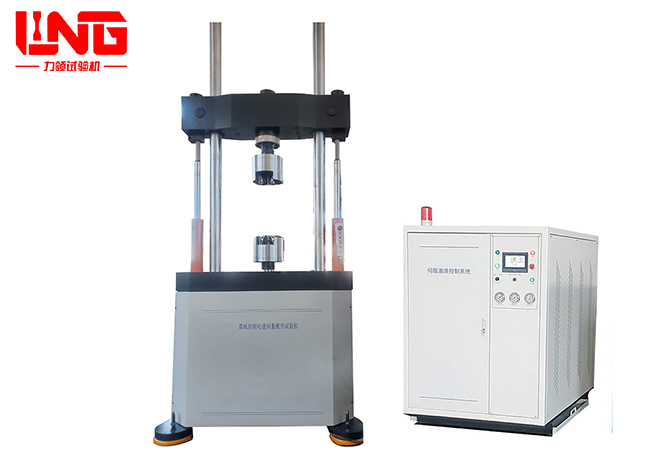

- Dynamic fatigue testing machine

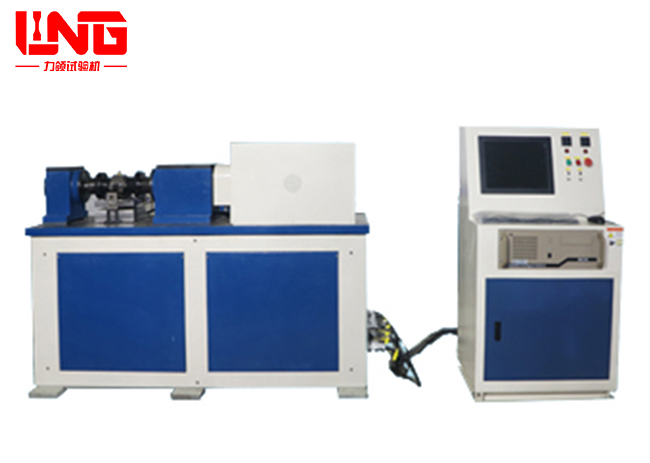

- Friction and wear testing machine

- Fastener special testing machine

- Static mechanical property testing machine

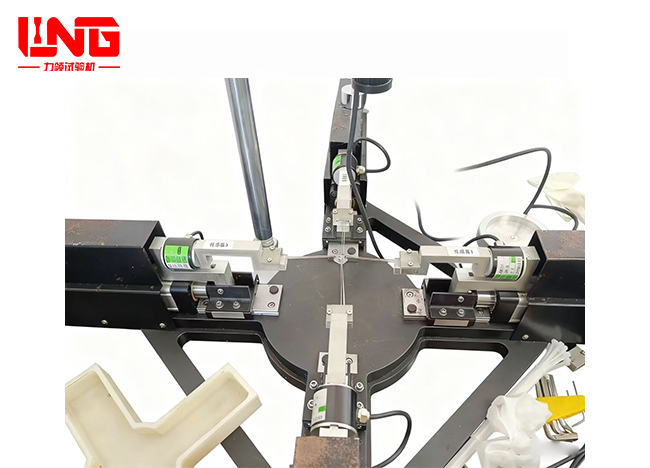

- In-situ tensile testing machine

- Non-standard customized large and small mechanical equipment

- Metallographic sample preparation and analysis equipment

- hardmeter

- Solution of overall design and planning of laboratory

JBW-300HY Instrumented low-temperature automatic impact testing machine

Instrumental pendulum impact testing machine is usually called digital pendulum impact testing machine (also called oscillometric impact testing machine before computer technology is applied), which is a high-end product of pendulum impact testing machine at present.

Introduction

A force sensor is attached to an ordinary impact testing machine to test the force on the sample during the impact process, and the voltage signal output by the force sensor is converted into a digital signal. After data storage and software calculation, the collected signals are drawn into curves of impact force-time, impact force-displacement, displacement-time and energy-time, and the force and deformation process of the punched sample are vividly given, and the energy absorbed by the sample can be decomposed into crack shape success and crack propagation work, so that a short-term dynamic load impact test can be carried out. This kind of impact tester is called instrumented impact tester.

Instrumentation shock is the product of digital age. Judging from the impact performance indexes of materials, it not only improves the accuracy and increases the number of indexes, but also provides the possibility for the standardization of impact tests, which is a qualitative change of impact tests and creates good conditions for the in-depth popularization and application of impact tests.

Instrumental impact testing machine will be the replacement and development direction of the current ordinary impact testing machine;

Parameters

|

Category |

Parameter |

Specification |

|

(一) Main Unit Parameters |

Pre-lift Angle of Pendulum |

150° |

|

|

Distance from Pendulum Axis to Strike Center |

750 mm |

|

(二) Measurement Parameters |

Maximum Impact Energy |

300 J |

|

|

Impact Velocity |

5.24 m/s |

|

|

Angle Accuracy |

0.06° |

|

|

Angle Resolution |

0.015° |

|

|

Force Sensor Accuracy |

≤ ±1% |

|

|

Energy Resolution |

0.1 J |

|

|

Dial Scale Minimum Division |

2 J/division |

|

(三) Fixture Parameters |

Anvil Span |

40 mm |

|

|

Anvil Fillet Radius |

R1 - 1.5 mm |

|

|

Anvil Bevel Angle |

11° ± 1° |

|

|

Striker Edge Angle |

30° ± 1° |