News (click to select category)

Classification of hydraulic universal testing machines

Date:2023-08-04ID: 230Heat:

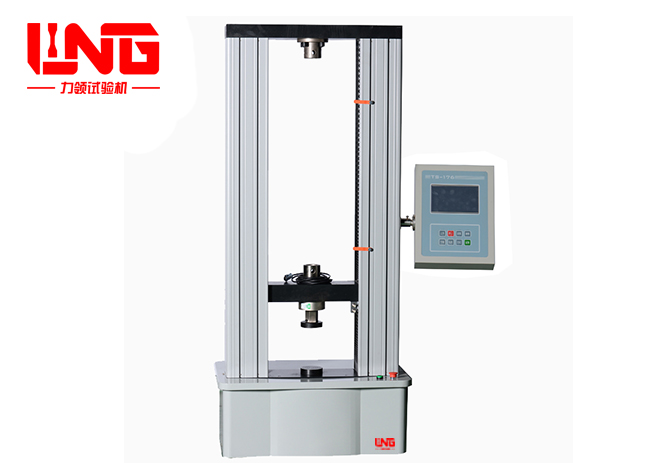

Hydraulic universal testing machine is a hydraulic material testing machine that can perform various tests such as tension, compression, bending, etc. The hydraulic universal testing machine is used for tensile, compression, bending, and shear tests of various metal and non-metal materials, as well as special tests of some products. The test operation and data processing comply with the requirements of standards such as GB228-2010 "Room Temperature Material Metal Tensile Test Method". Next, let's take a look at the classification and uses of hydraulic universal testing machines with me.

The hydraulic universal testing machine is mainly used for mechanical property testing of metal, non-metal, composite materials and products through tensile, compressive, bending, shear and other methods. At the same time, it can conduct tests and data processing according to GB, ISO, JIS, ASTM, DIN and various standards provided by users. Widely used in industries such as aerospace, machinery manufacturing, wire and cable, rubber and plastic, and building materials for material inspection and analysis, it is an ideal testing equipment for research institutes, colleges and universities, industrial and mining enterprises, technical supervision, commercial inspection and arbitration departments.

Hydraulic universal testing machines are generally divided into four categories: 1100KN, 300KN, 600KN, and 000KN, which are relatively simple compared to the wide variety of electronic universal testing machines;

The hydraulic universal testing machine is refined into three major categories and a total of 12 conventional types in this technology:

Digital display hydraulic universal testing machine: 100KN, 300KN, 600KN, 1000KN.

Screen display (computer display) hydraulic universal testing machine: 100KN, 300KN, 600KN, 1000KN.

Microcomputer controlled (fully automatic) hydraulic universal testing machine: 100KN, 300KN, 600KN, 1000KN.

According to the tightening method, there are generally two types: manual and hydraulic.

According to the adjustment method of the screw, it can be divided into (the most common): chain type and worm gear type.

According to the equipment grade, it can be divided into B-type machine, C-type machine, D-type machine, and A-type machine from the 1990s (which has been phased out).

Note: Except for Type A machine, B, C, and D are all main engines under the oil cylinder.

The hydraulic universal testing machine is mainly used for mechanical property testing of metal, non-metal, composite materials and products through tensile, compressive, bending, shear and other methods. At the same time, it can conduct tests and data processing according to GB, ISO, JIS, ASTM, DIN and various standards provided by users. Widely used in industries such as aerospace, machinery manufacturing, wire and cable, rubber and plastic, and building materials for material inspection and analysis, it is an ideal testing equipment for research institutes, colleges and universities, industrial and mining enterprises, technical supervision, commercial inspection and arbitration departments.

Hydraulic universal testing machines are generally divided into four categories: 1100KN, 300KN, 600KN, and 000KN, which are relatively simple compared to the wide variety of electronic universal testing machines;

The hydraulic universal testing machine is refined into three major categories and a total of 12 conventional types in this technology:

Digital display hydraulic universal testing machine: 100KN, 300KN, 600KN, 1000KN.

Screen display (computer display) hydraulic universal testing machine: 100KN, 300KN, 600KN, 1000KN.

Microcomputer controlled (fully automatic) hydraulic universal testing machine: 100KN, 300KN, 600KN, 1000KN.

According to the tightening method, there are generally two types: manual and hydraulic.

According to the adjustment method of the screw, it can be divided into (the most common): chain type and worm gear type.

According to the equipment grade, it can be divided into B-type machine, C-type machine, D-type machine, and A-type machine from the 1990s (which has been phased out).

Note: Except for Type A machine, B, C, and D are all main engines under the oil cylinder.

Previous: Recently, a Chinese weapons research and production base in Gansu purchased our company's microelectromechanical hydraulic servo universal testing machine. The equipment was successfully delivered and accepted, and the customer was very satisfied.Next: Precautions for installation and commissioning of fully automatic bending and compression resistant integrated machine