Precautions for installation and commissioning of fully automatic bending and compression resistant integrated machine

Jinan Liling Testing Machine Co., Ltd. Installation and commissioning precautions for fully automatic bending and compression resistant integrated machine:

1. The equipment and its accessories are packed in a packaging box, and the outer packaging should be checked for integrity before opening the box. After opening the box, take out the random technical files, then check whether the components inside the packaging box are intact, and verify whether there are any missing parts according to the packing list.

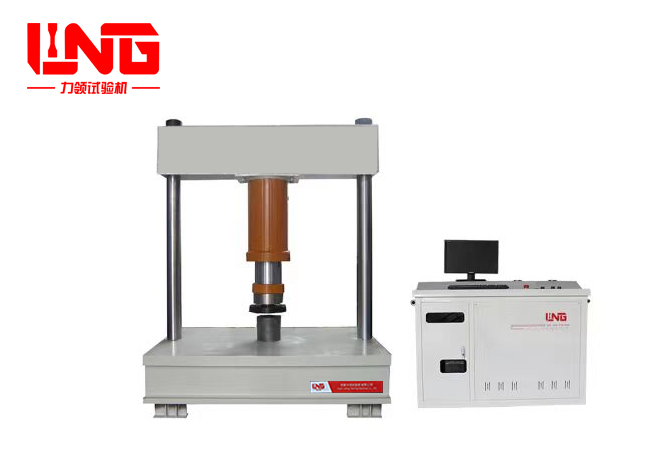

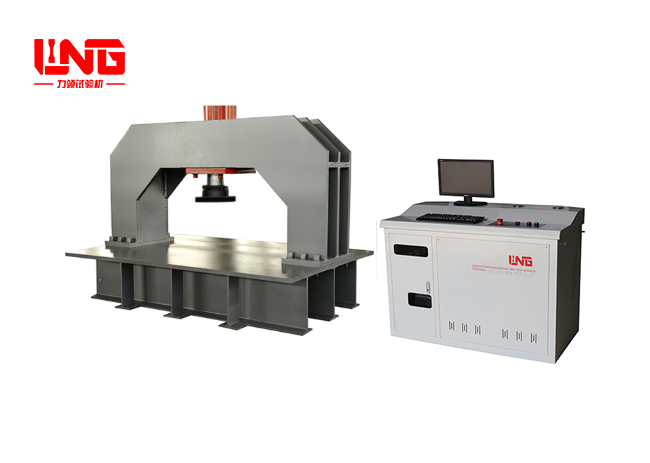

2. Refer to the overall appearance diagram (attached image), place the equipment on a sturdy and horizontal concrete floor, and connect it with M10 expansion bolts at the four foot holes of the main engine. Place the remaining parts correctly.

3. Distribution and wiring: The power supply system of this equipment is single-phase 220V AC power supply, with a power supply of approximately 1600W. Connect the power plug to the pre prepared power socket, and be careful not to connect the neutral, live, and ground wires incorrectly.

4. Leveling: Use a 0.02/1000 frame level to adjust the level of the host, and if necessary, use an adjusting iron pad under the host to adjust its level.

5. Stability of the host: After the debugging of the testing machine is completed, tighten the expansion bolts and recheck the installation accuracy of the testing machine. Generally, the level should be rechecked regularly.