News (click to select category)

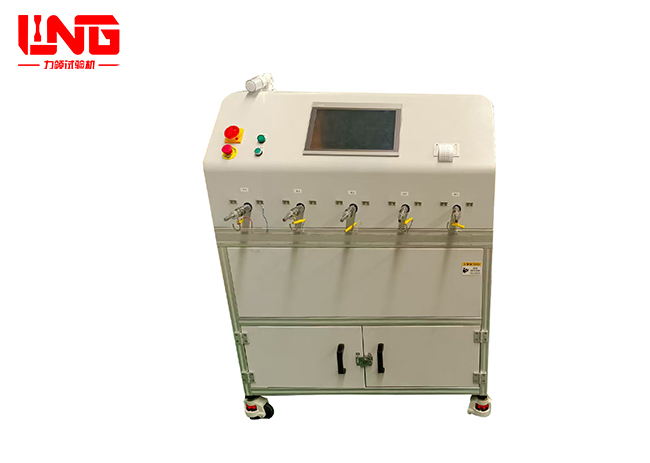

Leading the new standard for material testing: Jinan Leading proudly launches high-performance shaft sleeve friction and wear testing machine

Date:2025-09-19ID: 257Heat:

Jinan Liling Testing Machine Co., Ltd., a domestic manufacturer in the field of material performance testing, officially announced today the launch of a new independently developed high-precision shaft sleeve friction and wear testing machine.

With the rapid development of industrial technology, unprecedented high standards have been put forward for the reliability, durability, and service life of mechanical basic components such as bearings, shaft sleeves, sliders, etc. Traditional testing methods often suffer from pain points such as insufficient accuracy, single simulation of working conditions, and incomplete data collection. Jinan Leading has been deeply involved in the field of testing machines for many years, with a deep understanding of industry needs. The new generation of shaft sleeve friction and wear testing machine launched this time is designed to solve these core pain points.

Core technological advantages and characteristics:

Accurate working condition simulation capability: The testing machine can accurately simulate the actual working state of the shaft sleeve under different speeds, loads, temperatures, and lubrication conditions, supporting the application of static, dynamic, and alternating composite loads. The test results can better reflect the performance of the components under actual working conditions.

High precision data acquisition system: equipped with imported high-precision sensors and high-speed data acquisition cards, it can monitor and record key parameters such as friction torque, wear amount, temperature rise, and speed in real time and continuously. The data curve is smooth, providing a solid data foundation for in-depth analysis of friction and wear mechanisms.

Humanized intelligent operation: using industrial grade touch screen and professional measurement and control software, the interface is intuitive and the operation is simple. Users can pre-set complex testing processes to achieve automated operation. The software has powerful data management, curve analysis, and report generation functions, greatly improving testing efficiency.

Stable structure and safety: The host is made of high-strength cast iron and high-quality alloy structural steel, which have undergone precision machining and aging treatment to ensure high rigidity, high stability, and long service life of the entire machine. The equipment is equipped with multiple safety protection devices (such as overload protection, over temperature protection, emergency stop, etc.) to ensure the safety of operators and equipment.

High scalability and customization: Provides a variety of fixtures and accessory options to meet the testing needs of different types and sizes of shaft sleeve samples. The company supports customized development based on customers' special testing requirements and provides one-stop testing solutions.

With the rapid development of industrial technology, unprecedented high standards have been put forward for the reliability, durability, and service life of mechanical basic components such as bearings, shaft sleeves, sliders, etc. Traditional testing methods often suffer from pain points such as insufficient accuracy, single simulation of working conditions, and incomplete data collection. Jinan Leading has been deeply involved in the field of testing machines for many years, with a deep understanding of industry needs. The new generation of shaft sleeve friction and wear testing machine launched this time is designed to solve these core pain points.

Core technological advantages and characteristics:

Accurate working condition simulation capability: The testing machine can accurately simulate the actual working state of the shaft sleeve under different speeds, loads, temperatures, and lubrication conditions, supporting the application of static, dynamic, and alternating composite loads. The test results can better reflect the performance of the components under actual working conditions.

High precision data acquisition system: equipped with imported high-precision sensors and high-speed data acquisition cards, it can monitor and record key parameters such as friction torque, wear amount, temperature rise, and speed in real time and continuously. The data curve is smooth, providing a solid data foundation for in-depth analysis of friction and wear mechanisms.

Humanized intelligent operation: using industrial grade touch screen and professional measurement and control software, the interface is intuitive and the operation is simple. Users can pre-set complex testing processes to achieve automated operation. The software has powerful data management, curve analysis, and report generation functions, greatly improving testing efficiency.

Stable structure and safety: The host is made of high-strength cast iron and high-quality alloy structural steel, which have undergone precision machining and aging treatment to ensure high rigidity, high stability, and long service life of the entire machine. The equipment is equipped with multiple safety protection devices (such as overload protection, over temperature protection, emergency stop, etc.) to ensure the safety of operators and equipment.

High scalability and customization: Provides a variety of fixtures and accessory options to meet the testing needs of different types and sizes of shaft sleeve samples. The company supports customized development based on customers' special testing requirements and provides one-stop testing solutions.