The quality of testing machines varies greatly. How should customers choose a testing machine?

Before a test sample or material is officially put into mass production and manufacturing, and before entering the market, its quality, structure, and performance must be strictly tested. At this time, certain standards must be established with the help of precise and highly sensitive testing machines. Any equipment used for quality and physical performance testing of products and materials can be called a testing machine. The indicators it tests are usually yield strength, impact resistance, toughness, tensile strength, etc. If the equipment is used to test the chemical properties of products or materials, it cannot be called a testing machine, but should be called an analyzer.

The usage conditions and environment of the testing machine are not strict, and it can effectively test products and materials under any conditions. And these products and materials include mechanical parts, engineering structures, metallic materials, non-metallic materials, etc. It mainly detects the physical and mechanical properties, process performance, internal defects of these products and materials, as well as verifies the dynamic imbalance of rotating internal parts, and compares them with national standards to determine whether they can be launched.

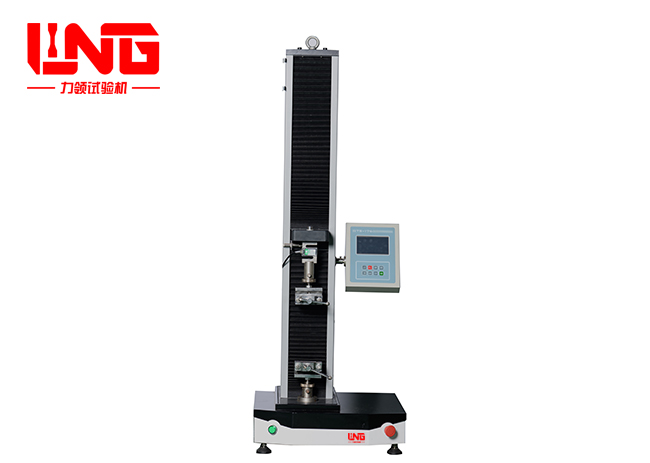

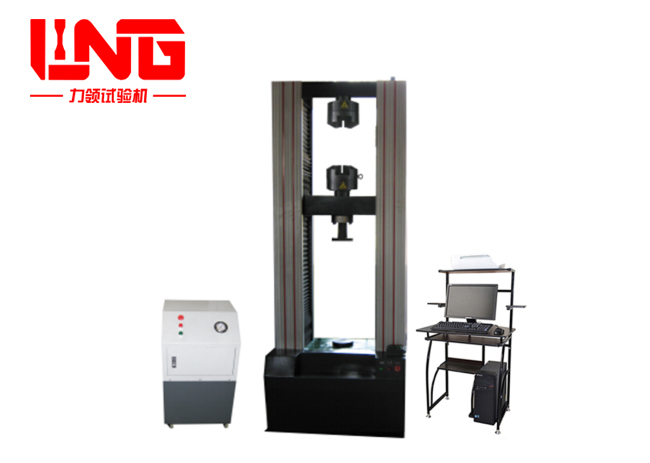

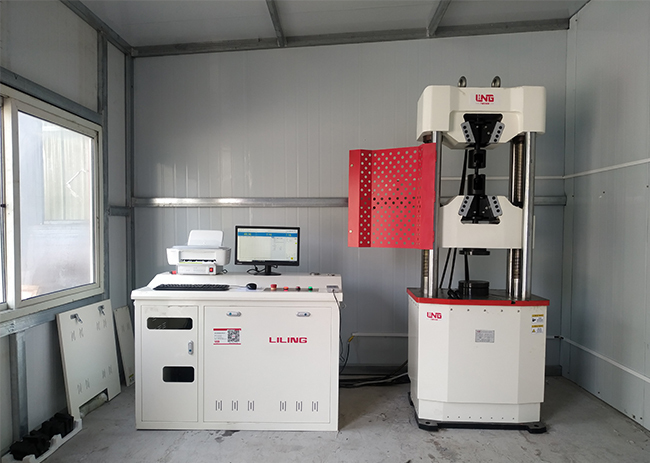

Due to differences in the application scope of testing machines, they are divided into many varieties. The first type to be introduced is the impact testing machine, which is used to test the resistance of metal or non-metal materials to impact under dynamic loads, so as to accurately determine the properties and performance of products or materials under dynamic load stimulation. The second type is the impact test low-temperature instrument, which is a device suitable for metal materials and is currently a suitable sample cooling and insulation device for metal materials in low-temperature impact tests. The third type is the impact specimen notch lathe, which is used to process the notch of the specimen. The fourth type is the impact specimen notch projector, which can be used to test whether the notches of the processed products comply with the qualified standards. The fifth type is a material testing machine, which is a device used to test the mechanical and process properties of materials, components, parts, and other substances. It can test tension, elasticity, pressure, shaping, strength, stiffness, etc.

The testing machine has been put into use in industries such as engineering quality supervision stations, metallurgical plants, construction industry, industrial and mining enterprises, light industry, aerospace, materials, universities, and research institutions. Its high precision, low noise, smooth operation, easy operation, and diverse functions have impressed industry insiders.