What is a universal testing machine

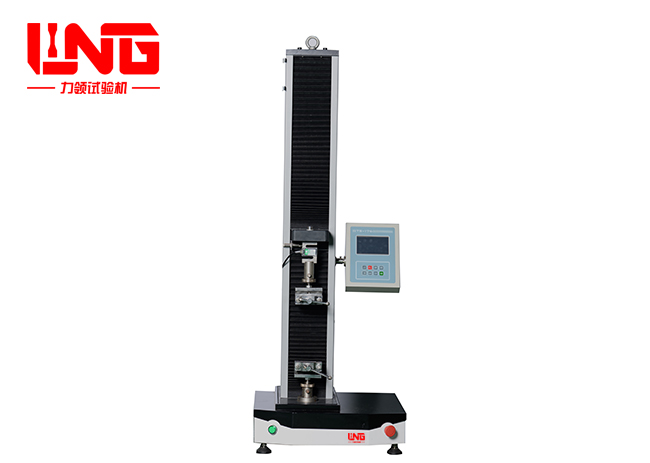

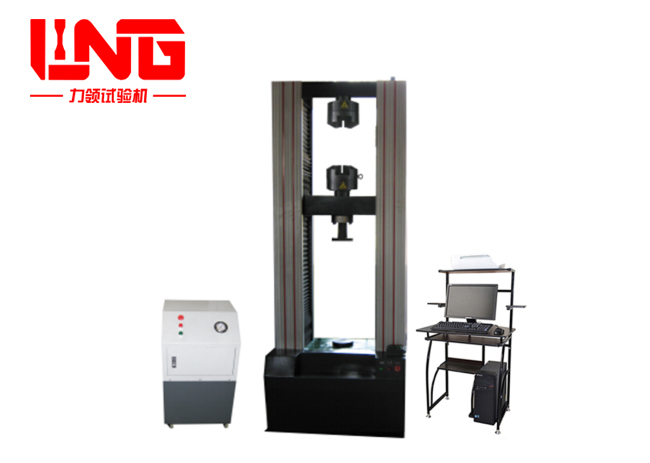

A universal testing machine is a testing machine that can perform three or more functions, such as tensile, compressive, bending, shear and other mechanical performance tests. Electronic universal testingMachineGenerally, it is relatively small. For non-metallic material testing, electronic universal testing machines are usually chosen. There are domestic and imported configurations, with level 1 accuracy and level 0.5 accuracy.Hydraulic universal testing machinesare generally large tonnage and suitable for metal material testing. There are also domestic and imported configurations, with level 1 standards and level 0.5 standards..

The tensile force is a test force that extends along the longitudinal axis of the specimen but in the opposite direction, causing the specimen to undergo elongation deformation.

The most basic mechanical property testing method for tensile testing. It refers to the application of tensile load along the longitudinal axis of a specimen under specified temperature and test rate conditions to fracture it, in order to determine the mechanical properties of the material such as elastic modulus, tensile strength, yield strength, growth rate, etc.

The test force that applies pressure vertically to the upper and lower end faces of the specimen, causing deformation due to compression.

Compression test is the most basic mechanical performance testing method. A test conducted at room temperature to determine the mechanical properties of a material by applying a compressive load to the specimen.