The advantages and disadvantages of the stiffness of the testing machine

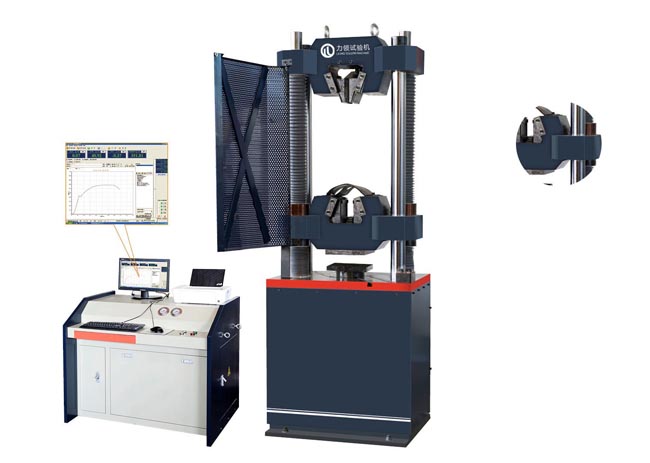

During the production and processing process, high rigidity is required for the testing machine, such as the hydraulic universal testing machine. If the rigidity of the testing machine is too small, there may be safety issues. A testing machine with poor rigidity can be called a disposable testing machine, and its long-term use cannot be guaranteed. So the stiffness of the testing machine is very important for the overall performance of the testing machine!

What are the main factors that affect the stiffness (or flexibility) of the testing machine?

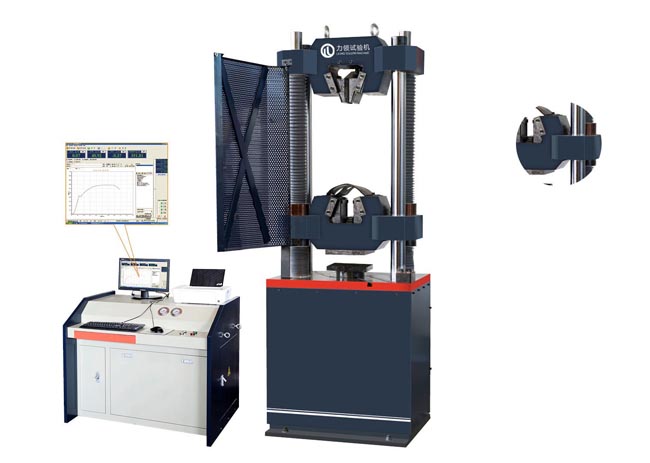

1. Is the design structure more reasonable, such as the B-type machine not being as good as the fully symmetrical structure of the D-type machine;

2. The materials used are too economical: the columns and screws are too thin; The upper and lower crossbeams are too thin;

3. Poor material quality: using low specification, low price, and inferior steel;

4. Labor is too economical: materials that should be tempered are not tempered; Materials that should be quenched are not quenched;

What are the hazards of using a testing machine with too little stiffness (or flexibility) for customers? A testing machine with poor stiffness can be called a disposable testing machine.

The low stiffness of the testing machine essentially means that the safety factor of the testing machine has not been considered, and it is a low-quality product. It will seriously reduce the fatigue performance of the testing machine and shorten its service life. Even crossbeams may occur. The phenomenon of column fracture and injury.