- Dynamic fatigue testing machine

- Friction and wear testing machine

- Fastener special testing machine

- Static mechanical property testing machine

- In-situ tensile testing machine

- Non-standard customized large and small mechanical equipment

- Metallographic sample preparation and analysis equipment

- hardmeter

- Solution of overall design and planning of laboratory

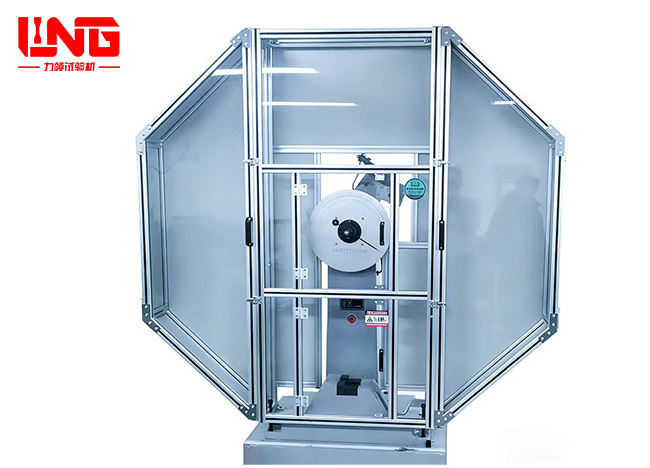

JBW-300B Microcomputer Screen Display Automatic Impact Tester

Microcomputer screen display automatic impact testing machine is mainly used to measure the impact resistance of metal materials under dynamic load, so as to judge the properties of materials under dynamic load.

Introduction

Microcomputer screen display automatic impact testing machine is mainly used to measure the impact resistance of metal materials under dynamic load, so as to judge the properties of materials under dynamic load.

This machine is a microcomputer screen display semi-automatic impact testing machine, which is controlled by PC microcomputer, and has high working efficiency and high testing accuracy, such as electric swing, impact, microcomputer measurement, calculation, digital display of results on the screen and printing. After impacting the sample, it can automatically swing by using the residual energy to prepare for the next test, with simple operation and high work efficiency. Its advantages can be better reflected in the laboratory where impact tests are conducted continuously and in metallurgy, machinery manufacturing and other industries where a large number of impact tests are conducted. The computer can calculate and display the impact absorption work, impact toughness, pendulum angle and test average value of materials, and can print the test data and test average value of the time.

According to GB/T3808-2018 (inspection of pendulum impact tester), ISO148-2 (pendulum impact test of metallic materials Part II, testing machine verification) and ASTM E23, the products are manufactured in accordance with GB/T229-2020 (Charpy notch impact test method of metallic materials), ISO148 (pendulum Charpy impact test of metallic materials) and JJG10.

Parameters

|

Parameter |

Specification |

|

Basic Specifications |

|

|

Impact Energy |

150 J, 300 J |

|

Pendulum Pre-lift Angle |

150° |

|

Distance from Pendulum Axis to Impact Point |

750 mm |

|

Impact Velocity |

5.2 m/s |

|

Specimen & Fixture |

|

|

Specimen Support Span |

40 mm |

|

V-notch Anvil Fillet Radius |

R1 - 1.5 mm |

|

Striker (Hammer) |

|

|

Striker Edge Radius |

R2 - 2.5 mm |

|

Striker (Hammer) Thickness |

16 mm |

|

Accuracy |

|

|

Angle Accuracy |

±0.1° |

|

Standard Specimen |

|

|

Specimen Dimensions |

10 mm × 10 mm × 55 mm |

|

Drive & Dimensions |

|

|

Drive Method |

Two-stage Gear Reducer Drive |

|

Overall Dimensions (L×W×H) |

2124 mm × 600 mm × 1340 mm |

|

Net Weight |

450 kg |

|

Power & Environment |

|

|

Power Supply |

AC 3-Phase, 380V ±10%, 50 Hz, 5A |

|

Environmental Conditions |

Free from corrosive media, vibration, and strong electromagnetic interference. |