- Dynamic fatigue testing machine

- Friction and wear testing machine

- Fastener special testing machine

- Static mechanical property testing machine

- In-situ tensile testing machine

- Non-standard customized large and small mechanical equipment

- Metallographic sample preparation and analysis equipment

- hardmeter

- Solution of overall design and planning of laboratory

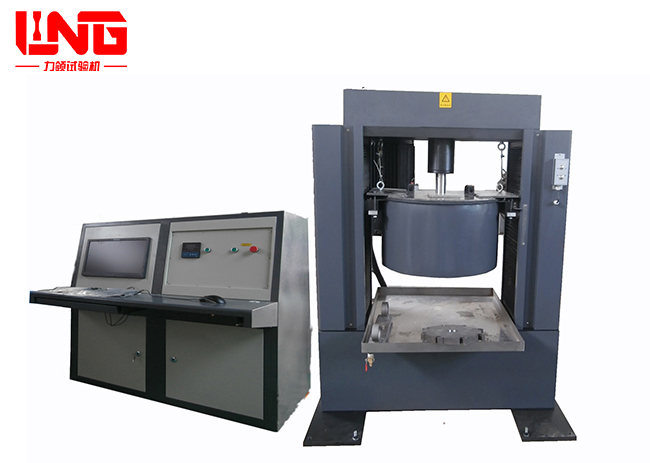

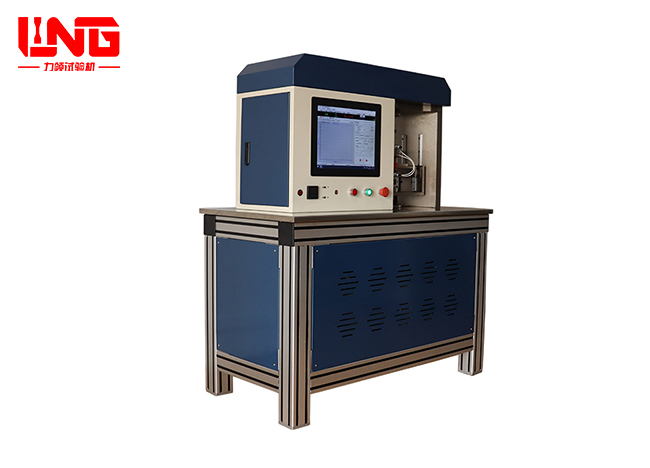

LPWH-600 Rubber product axial linear reciprocating friction test bench

Rubber product axial linear reciprocating friction test bench

Introduction

The core of the axial linear reciprocating friction test bench for rubber products is used to simulate the axial reciprocating motion state of rubber products (outer diameter 260mm) and mating parts (inner diameter 260mm cylinder) in actual work. By accurately controlling the test parameters, the friction coefficient, wear amount, sealing performance, and durability between the two are tested, providing scientific and reliable test data support for product design optimization, material screening, and quality inspection of rubber products, ensuring the sealing reliability and service life of products under actual working conditions.

This test bench is suitable for axial reciprocating friction and wear testing and durability testing of rubber products with an outer diameter of 260mm (such as hydraulic cylinder seals, engineering machinery seals, etc.) and corresponding inner diameter of 260mm cylinder matching parts. It can be widely used in product research and development, quality control, and performance verification of seal production enterprises, research institutes, and testing institutions.

Parameters

|

No. |

Parameter Name |

Technical Specification |

Remarks |

|

1 |

Reciprocating Motion Type |

Axial Linear Reciprocating |

No eccentricity, no swing. |

|

2 |

Reciprocating Stroke |

0-600mm, continuously adjustable. |

Accuracy: ±1mm; Resolution: 0.1mm. |

|

3 |

Reciprocating Frequency |

0.01-0.4Hz, continuously adjustable. |

Accuracy: ±0.01Hz; No significant frequency fluctuation. |

|

4 |

Rubber Seal Sleeve Spec. |

Outer Diameter: Φ260mm. |

Inner diameter and height adaptable to the clamping mechanism; Replaceable. |

|

5 |

Mating Part Spec. |

Cylinder barrel, Inner Diameter: Φ260mm. |

Material optional; Surface roughness Ra ≤ 0.8μm. |

|

6 |

Concentricity Error |

≤ 0.02mm. |

Between the seal sleeve and cylinder barrel. |

|

7 |

Test Duration |

0-1000 hours, continuous operation. |

Supports breakpoint resume; Automatic time recording. |

|

8 |

Measured Parameters |

Friction force, Displacement, Frequency, etc. |

Real-time data acquisition; Accuracy meets test requirements. |

|

9 |

Test Environment |

Standard temp. & humidity (23±2°C, 50±5% RH). |

Optional high/low temp. (-40°C ~ 150°C) and medium immersion modules. |

|

10 |

Equipment Power |

2.5 kW. |

AC380V, 50Hz. |

|

11 |

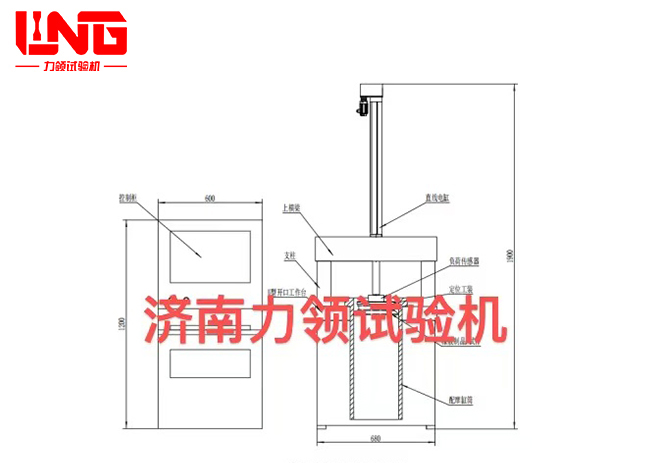

Equipment Dimensions |

Approx. 600mm × 500mm × 1500mm (L × W × H). |

Slight adjustments possible based on site space. |