- Dynamic fatigue testing machine

- Friction and wear testing machine

- Fastener special testing machine

- Static mechanical property testing machine

- In-situ tensile testing machine

- Non-standard customized large and small mechanical equipment

- Metallographic sample preparation and analysis equipment

- hardmeter

- Solution of overall design and planning of laboratory

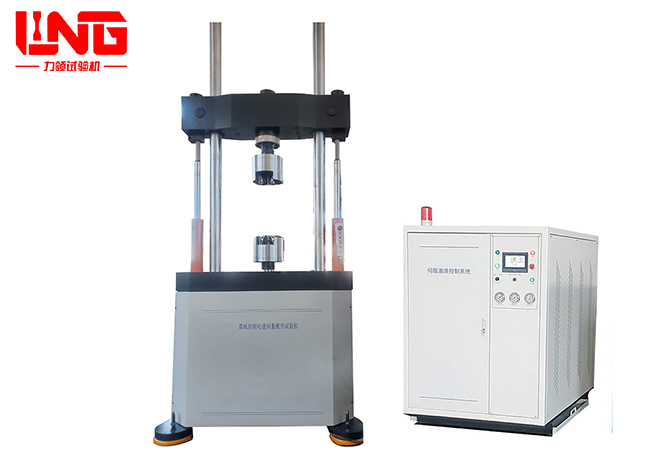

LPA-200 Electro hydraulic servo fatigue testing machine

The LPA-200 electro-hydraulic servo fatigue testing machine is a single axis axial loading testing machine, which consists of a servo valve as the control core and a controller to form an automatic control system. It is mainly used for fatigue testing of material samples and components. Furthermore, it reaches the S-N curve of the material or component, which is the stress life relationship curve.

Introduction

1.The LPA-200 electro-hydraulic servo fatigue testing machine is a single axis axial loading testing machine, which consists of a servo valve as the control core and a controller to form an automatic control system. It is mainly used for fatigue testing of material samples and components. Furthermore, it reaches the S-N curve of the material or component, which is the stress life relationship curve.

2. Control methods include force control and displacement control;

3. Equipped with high cycle testing and low cycle fatigue testing functions, the loading waveforms include sine wave, triangular wave, oblique wave, square wave, and custom loading waveforms.

4. The fully digital measurement controller independently developed and produced adopts the Dutch ARM chip, network port communication, easy connection, safety and reliability.

5. Adopting a 100KN, 0.05% FS nonlinearity American Celtron force sensor, and a hysteresis displacement meter with ± 75mm, 0.2% FS nonlinearity.

Parameters

|

Parameter |

Specification |

|

Maximum Static Test Force |

±200 kN |

|

Maximum Dynamic Test Force |

±150 kN |

|

Force Accuracy Guaranteed Range |

2% FS to 100% FS |

|

Static Force Indication Accuracy |

≤ ±1% |

|

Dynamic Force Indication Accuracy |

≤ ±2% |

|

Displacement Resolution |

0.01 mm |

|

Maximum Displacement/Amplitude |

100 mm |

|

Displacement Indication Accuracy |

≤ ±1% |

|

Actuator Maximum Amplitude |

100 mm, ±50 mm |

|

Test Frequency Range |

0.1 to 50 Hz |

|

Test Waveforms |

Sine, Triangle, Trapezoidal, etc. |

|

Control Modes |

Force, Displacement |

|

Fixture Configuration |

Hydraulic Grips |

|

Clamping Method |

Hydraulic automatic clamping, button control |

|

Gripping Range |

Standard Plate Grips: Thk. 4-9mm, 9-14mm, 14-19mm; Width ≤40mm |

|

|

Standard Round Bar Grips: Ø9-14mm, Ø14-19mm, Ø19-24mm |

|

Clear Distance Between Columns |

540 mm (Customizable) |

|

Distance Between Upper/Lower Grips (adjustable) |

50-550 mm (Customizable) |

|

Host Machine Dimensions (W x D x H) |

1200 x 600 x 2600 mm (Height adjustable with test space) |

|

Hydraulic Power Unit Flow Rate |

40 L/min |

|

Hydraulic Power Unit Dimensions (W x D x H) |

1800 x 1600 x 2000 mm |

|

Main Power Supply |

380V ±10%, 50Hz, 25kW |

|

Control Power Supply |

220V ±10%, 50Hz, 2kW |

|

Host Machine Weight |

2600 kg |