- Dynamic fatigue testing machine

- Friction and wear testing machine

- Fastener special testing machine

- Static mechanical property testing machine

- In-situ tensile testing machine

- Non-standard customized large and small mechanical equipment

- Metallographic sample preparation and analysis equipment

- hardmeter

- Solution of overall design and planning of laboratory

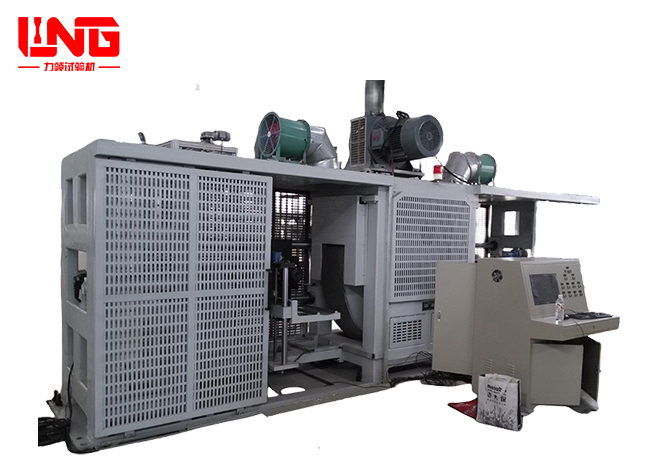

PWS-20 Electro-hydraulic servo railway elastic fatigue testing machine

Electro-hydraulic servo dynamic and static universal testing machine is widely used in dynamic and static mechanical properties tests of materials and parts, including tensile, compression, low cycle and high cycle fatigue tests of materials and parts. Equipped with high and low temperature boxes, high and low temperature mechanical tests can be carried out.

Introduction

During the research and development of the electro-hydraulic servo dynamic and static universal series testing machine, we learned from the development and manufacturing experience of internationally renowned electro-hydraulic servo dynamic testing machine company, adopted the development concept of "unitization, modularization and standardization", absorbed the international advanced electro-hydraulic servo dynamic testing machine technology and combined with the actual use situation of domestic users. The key components of electro-hydraulic servo dynamic testing machine are famous brand products of similar products at home and abroad. The stability and reliability of the system are greatly improved. The key units and components of the system are manufactured by the international advanced technology, and the overall performance of the whole test system is equivalent to the technical level of the internationally renowned dynamic testing machine company. This series of products has the characteristics of convenient use, high control precision and good reliability.

20kN electro-hydraulic servo dynamic and static universal testing machine is one of the series of dynamic and static universal testing machines developed by our company. The main engine of the testing machine, constant pressure servo pump station, hydraulic chuck and other key components are designed and manufactured by our company. The key outsourcing parts such as servo valves and seals are famous brand products of similar products at home and abroad, which greatly improves the stability and reliability of the system. The overall performance of the testing machine is equivalent to the technical level of international advanced products. Meet TB/T2329-2002 (fatigue test method for elastic strips of type I and type II fasteners).

Parameters

|

Parameter |

Specification |

|

1. Maximum Dynamic Test Force |

≥ ±20 kN |

|

2. Test Force Measurement |

|

|

Range |

1% ~ 100% F.S. (Full-range, single range) |

|

Accuracy |

±1% F.S. |

|

3. Test Space |

|

|

3.1 Max. Adjustable Clear Space |

500 mm |

|

3.2 Effective Column Spacing |

600 mm |

|

4. Actuator Stroke |

±50 mm, Indicator Accuracy: ±0.5% |

|

5. System Accuracy |

|

|

5.1 Force & Deformation Measurement |

Better than ±0.5% of reading (Static) |

|

5.2 Displacement Measurement |

Better than ±0.5% of reading (Static/Dynamic) |

|

5.3 Mean Load Fluctuation |

±1% |

|

5.4 Dynamic Load Fluctuation |

±2% |

|

6. Test Waveforms |

Sine, Square, Triangle, Ramp, Sawtooth, User-defined |

|

7. Test Frequency |

0.01 - 20 Hz, Continuous operating frequency: 4-16 Hz |

|

8. Fatigue Cycles |

Up to 1×10⁷ cycles (Arbitrarily settable) |

|

9. Frame Stiffness |

3.3×10⁸ N/mm |

|

10. Control Modes |

Force, Displacement, Strain (PID closed-loop), |

|

11. Hydraulic Power Unit |

Flow rate ≥ 40 L/min, Pressure: 21 MPa |