- Dynamic fatigue testing machine

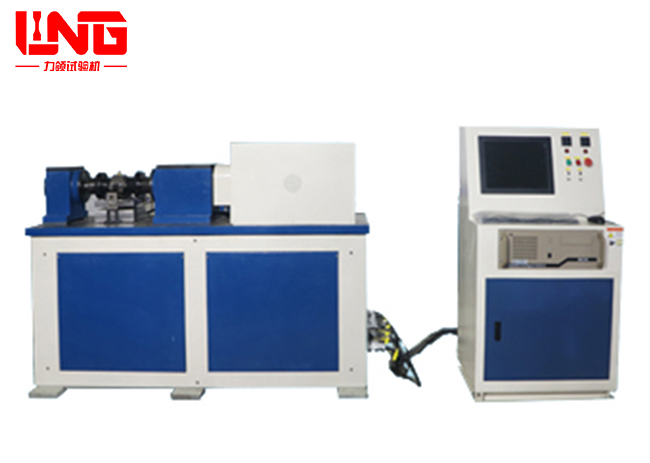

- Friction and wear testing machine

- Fastener special testing machine

- Static mechanical property testing machine

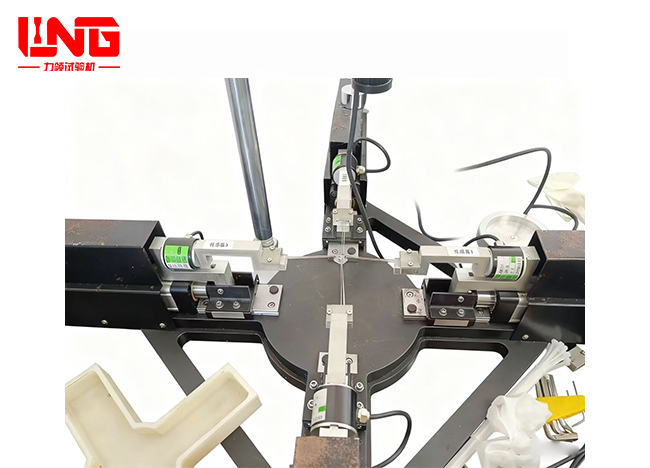

- In-situ tensile testing machine

- Non-standard customized large and small mechanical equipment

- Metallographic sample preparation and analysis equipment

- hardmeter

- Solution of overall design and planning of laboratory

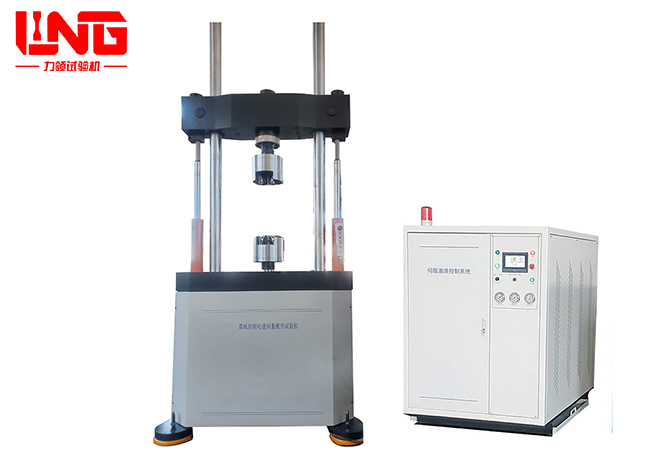

PWS-300 Rubber rail gasket fatigue testing machine

The electro-hydraulic servo fatigue series testing machine is used to conduct axial tension compression, tension tension, and compression compression fatigue tests on the tested sample.

Introduction

Main purpose: Used for fatigue testing, dynamic stiffness, static stiffness, longitudinal resistance testing, assembly buckle pressure testing, and other projects on high-speed railway fasteners, sub rail pads, and other components in the laboratory. The replacement of attachments is also applicable to various components such as concrete structural components, sleepers, steel strands, anchorages, and various trusses for dynamic and static mechanical performance testing.

Parameters

|

Parameter |

Specification |

|

Max. Static Test Force |

±300 kN |

|

Static Indication Accuracy |

±1% (from 2% to 100% of range) |

|

Max. Dynamic Test Force |

±300 kN |

|

Dynamic Force Fluctuation |

≤ ±1% FS |

|

Actuator Stroke |

±75 mm |

|

Stroke Indication Accuracy |

±0.5% FS |

|

Frequency Range |

0.01 - 20 Hz |

|

Control Modes |

Force, Displacement, Strain |

|

Main Test Waveforms |

Sine, Square, Triangle, Ramp waves |

|

Constant Pressure Servo Pump Station |

Flow: 40 L/min, Pressure: 21 MPa, Motor Power: 22 kW |