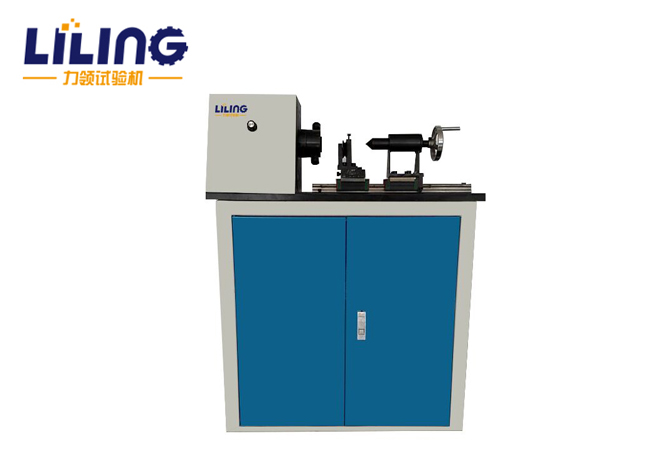

A new model of metal wire winding testing machine has been developed and released

1、 Usage and characteristics:

The metal wire winding testing machine is mainly used to test the adhesion and surface defects of the surface coating displayed on metal materials with and without coating after being subjected to winding deformation.

2、 Working principle:

The winding testing machine tightly wraps the on-site sample on a core rod with a specified diameter that meets relevant standards, with a specified number of spiral turns. This experiment can also include special procedures for winding, unwinding, and even rewinding. The experimental equipment should be able to meet the requirements of winding the wire around the core rod and arranging adjacent coils tightly in a spiral coil. The wire used for testing can also be used as a core rod as long as it meets the specified core rod diameter and has sufficient hardness.

Usage standard: This testing machine complies with the GB/T2976-2004/ISO standard; 7802:1993 Metal Materials; Cable Wrapping Test Method

3、 Function Introduction:

1. The experiment should generally be conducted at room temperature of10℃-35℃,

2. The sample is tightly wrapped around the core rod at a specified speed of no more than one turn per second along the spiral direction without any twisting. If necessary, the winding speed can be slowed down to prevent the temperature from rising and affecting the test results.

3. To ensure tight winding, a tension force not exceeding 5% of the corresponding nominal tensile strength of the wire can be applied at the free end of the sample during winding.

4. If it is required to unwind or unwind before rewinding, the speed of unwinding and rewinding should be as slow as possible to prevent temperature rise from affecting the test results. At least one winding loop should be retained at the end of the sample during unwinding.

5. The judgment of winding test results should be carried out in accordance with the relevant standards. If there are no specific requirements, the surface of the sample can be inspected without using magnifying tools. If no cracks are found, the sample is considered qualified. Wires with a diameter or thickness less than0.5mmshould be inspected at a magnification of approximately10times.

4、 Technical specifications:

1. Diameter range:0.5-6mm

2、 Winding speed: ∠60r/min (adjustable)

3. Motor power: approximately 12N. m

4. Self weight (kg): approximately220

5. Power supply:220V±10%.

6. Dimensions (mm): Approximately length x width x height 1200 x 400 x 955