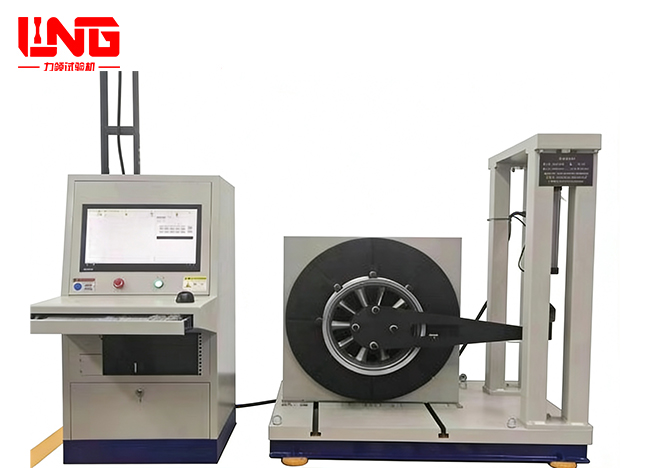

- Dynamic fatigue testing machine

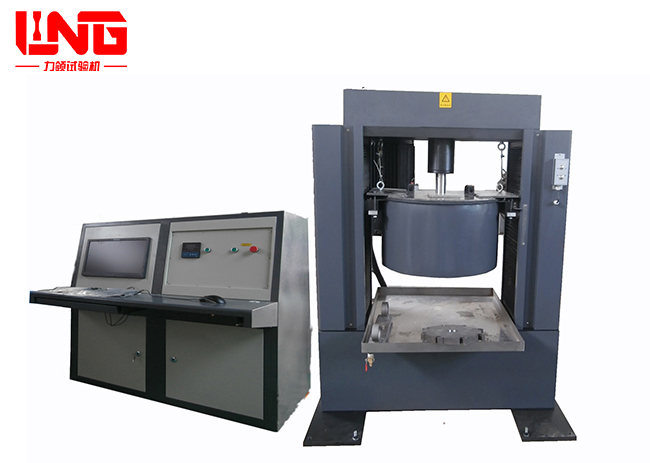

- Friction and wear testing machine

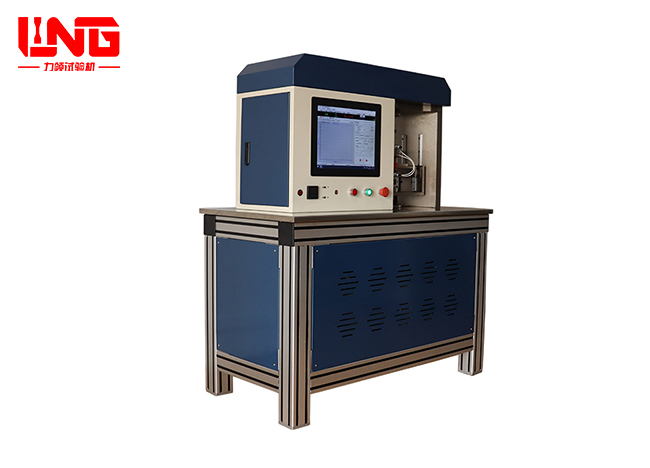

- Fastener special testing machine

- Static mechanical property testing machine

- In-situ tensile testing machine

- Non-standard customized large and small mechanical equipment

- Metallographic sample preparation and analysis equipment

- hardmeter

- Solution of overall design and planning of laboratory

PWS-25 Electro-hydraulic servo universal testing machine

The electro-hydraulic servo dynamic and static universal testing machine is widely used for testing the dynamic and static mechanical properties of materials and components, including tensile, compressive, low cycle, and high cycle fatigue tests.

Introduction

The research and development process of the electro-hydraulic servo dynamic universal series testing machine draws on the development and manufacturing experience of internationally renowned electro-hydraulic servo dynamic testing machine companies, adopting the development concept of "modularization, modularity, and standardization", absorbing advanced international electro-hydraulic servo dynamic testing machine technology, and designing it based on the actual usage conditions of domestic users. The key supporting components of the electro-hydraulic servo dynamic testing machine are selected from well-known brands of similar international and domestic products. The stability and reliability of the system have been greatly improved, and the key units and components of the system are manufactured using advanced international technology. The overall performance of the entire testing system is comparable to the product technology level of internationally renowned dynamic testing machine companies. This series of products has the characteristics of easy use, high control accuracy, and good reliability.

Parameters

|

Parameter |

Specification |

|

1. Max. Static Testing Force |

±25 kN |

|

Static Indicating Accuracy |

±0.5% of reading (Full range) |

|

2. Max. Dynamic Testing Force |

±25 kN |

|

Dynamic Fluctuation |

≤ ±0.5% |

|

3. Actuator Stroke (Peak-to-Peak) |

±150 mm |

|

Displacement Indicating Accuracy |

±0.5% of reading |

|

4. Frequency Range |

0.01 — 20 Hz |

|

5. Displacement Measurement Accuracy |

±0.5% of reading (Full range) |

|

6. Displacement Resolution |

0.01 mm (Magnetostrictive Displacement Sensor) |

|

7. Function Generator |

Multi-stage |

|

8. Counter |

999,999,999 (Pre-settable) |

|

9. Control Modes |

Force, Displacement, Strain |

|

Main Waveforms |

Sine, Square, Triangle, Ramp (Controller-based) |

|

10. Max Test Space (Height) |

700 mm |

|

11. Column Spacing |

600 mm |

|

12. Frame Stiffness |

3.3 × 10<sup>8</sup> N/mm |

|

13. Overall Dimensions (L × W × H) |

1100 mm × 800 mm × 2800 mm |

|

14. Operating Pressure |

21 MPa (210 bar) |

|

15. Constant Pressure Servo Pump Station |

|

|

Flow Rate |

40 L/min |

|

Pressure |

21 MPa |

|

Motor Power |

18.5 kW |

|

Motor Speed |

1450 rpm |