News (click to select category)

Jinan Leading Craftsmanship Delivers, Helps Shandong Automotive Parts Manufacturer Successfully Debug and Successfully Put into Production of Leaf Spring Fatigue Testing Machine

Date:2025-12-03ID: 270Heat:

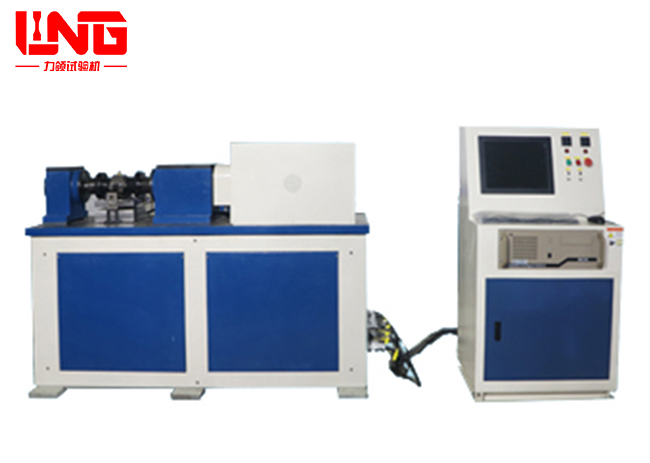

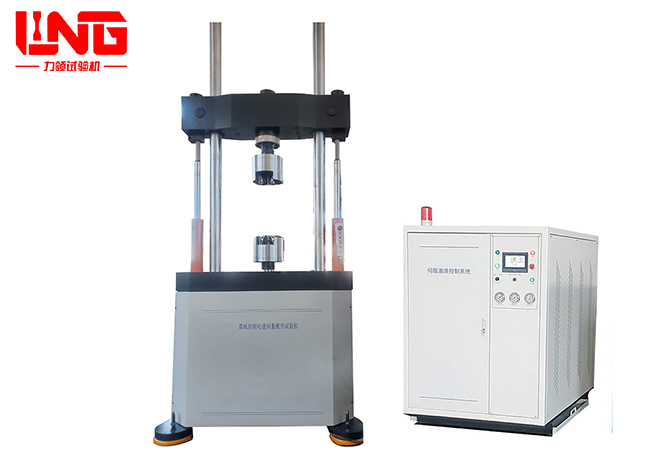

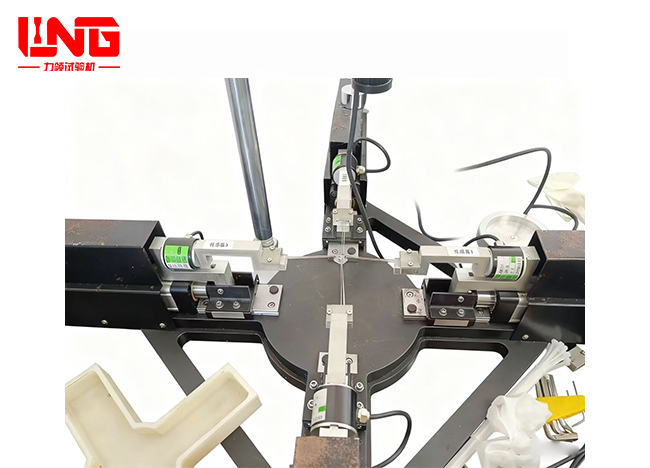

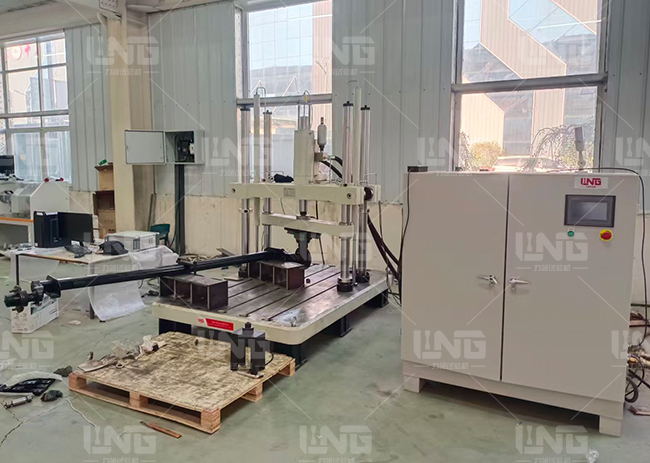

Recently, the high-performance leaf spring fatigue testing machine independently developed and designed by Jinan Liling Testing Machine Co., Ltd. was successfully installed, debugged, and trained on site at the production and testing center of a well-known automotive parts manufacturer in Shandong. At present, the equipment is running stably and all performance indicators are better than the agreed standards. It has been officially put into the customer's new product development and quality control process, and has been highly recognized by the customer's on-site personnel. The leaf spring fatigue testing machine delivered this time is one of Jinan Leading's flagship products, designed specifically for durability testing of automotive steel plate springs, air suspensions, and other components. To ensure that the equipment is put into operation in the best condition, Jinan Leading has dispatched a debugging team composed of senior engineers. After arriving at the customer's site, the team quickly put into work, overcame objective factors such as site, water and electricity, and efficiently completed the main lifting, horizontal calibration, and precise connection of the hydraulic system and electrical control system of the equipment.

During the debugging process, engineers repeatedly verified the core parameters of the testing machine, such as loading frequency, amplitude, waveform, and the accuracy of the data acquisition system. By simulating the extreme working conditions in actual customer production, the equipment has successfully completed hundreds of thousands of fatigue cycle tests. Its excellent stability and accuracy of test data fully verify the high reliability of Jinan Leading products.