Jinan Liling Electric Hydraulic Servo Universal Testing Machine Helps China University of Mining and Technology Overcome Difficulties in Rock Mechanics Testing

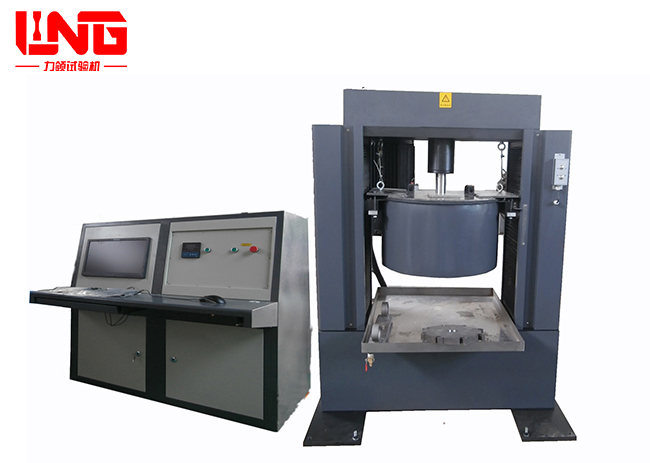

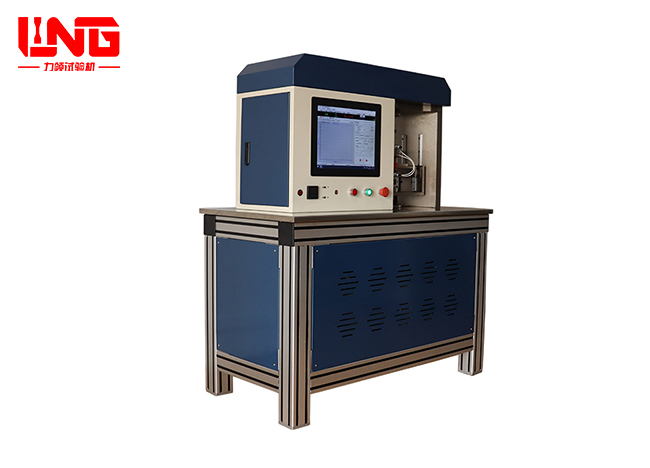

With the continuous deepening of deep earth resource development and geotechnical engineering research in China, high-end material testing equipment has become the key to ensuring the accuracy of scientific research data. Recently, China University of Mining and Technology (Xuzhou) introduced the HAW-600D microcomputer controlled electro-hydraulic servo universal testing machine developed by Jinan Liling Testing Machine Co., Ltd., which is used for a series of mechanical tests such as uniaxial compression, triaxial compression, Brazilian splitting, shearing, and metal material bending of rocks, providing key technical support for cutting-edge research on deep mining and energy storage.

The maximum test force of this testing machine is 600kN, with a force control accuracy of better than ± 0.5% and a displacement resolution of 0.001mm. It supports multiple testing modes such as tension, compression, and bending. Its core advantages lie in:

Fully closed-loop control: using an electro-hydraulic servo system to achieve precise control of force, displacement, and deformation parameters, meeting national standards such as GB/T 2611 and GB/T 16826;

Multi functional integration: Through modular fixture design, it can quickly switch between rock Brazilian splitting, metal three-point bending and other test scenarios, adapting to the diverse testing needs of China University of Mining and Technology for complex rock and soil samples

The collaborative innovation between Jinan Leading Testing Machine and China University of Mining and Technology demonstrates the potential application of domestic scientific instruments in high-end scientific research fields.