News (click to select category)

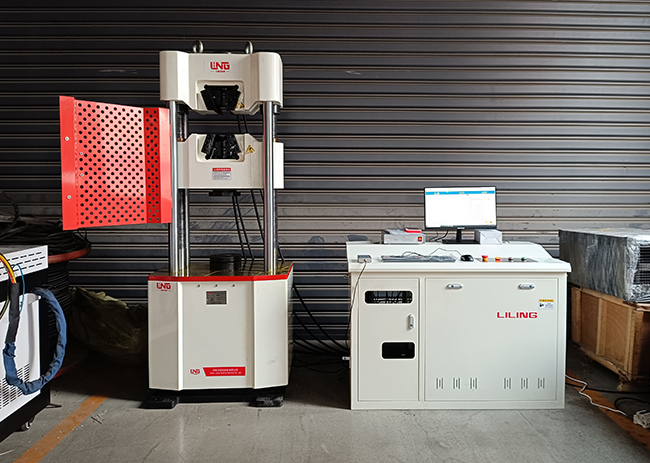

Preparation work before operating the electro-hydraulic servo hydraulic universal testing machine

Date:2025-12-22ID: 276Heat:

Pre-operation preparation

1. Confirm the 380V three-phase power supply, correctly connect the oil source to the host and the oil source to the computer, and turn the emergency stop button clockwise (red button on the operation panel) after connecting the main power supply.

2. There is no damage or leakage in the hydraulic pipeline, and the motor, servo valve, and sensor are operating normally;

3. Press the up and down buttons respectively, observe whether the crossbeam rises and falls, and whether the direction is consistent with the actual one (if not, you need to switch the two wire ends of the 380V power supply), and adjust the height of the crossbeam.

4. Press the oil pump start switch, run for 2 minutes, then turn off and observe if the workbench rises. Raise approximately 1-2 centimeters and close, then return the workbench to its original position.

If the workbench does not rise, there may be several reasons:

A: No hydraulic oil or too little;

B: There is an oil leak in the oil circuit;

5. Open computer software

Observe whether there are numerical values for load and displacement in the software to determine the connection. If there is no display, please check the connection (interface between load sensor and displacement sensor).

6. Personal protection: There are no unrelated personnel in the testing area. A safety cover should be closed for tensile testing, and sufficient buffer space should be reserved for compression testing.

1. Confirm the 380V three-phase power supply, correctly connect the oil source to the host and the oil source to the computer, and turn the emergency stop button clockwise (red button on the operation panel) after connecting the main power supply.

2. There is no damage or leakage in the hydraulic pipeline, and the motor, servo valve, and sensor are operating normally;

3. Press the up and down buttons respectively, observe whether the crossbeam rises and falls, and whether the direction is consistent with the actual one (if not, you need to switch the two wire ends of the 380V power supply), and adjust the height of the crossbeam.

4. Press the oil pump start switch, run for 2 minutes, then turn off and observe if the workbench rises. Raise approximately 1-2 centimeters and close, then return the workbench to its original position.

If the workbench does not rise, there may be several reasons:

A: No hydraulic oil or too little;

B: There is an oil leak in the oil circuit;

5. Open computer software

Observe whether there are numerical values for load and displacement in the software to determine the connection. If there is no display, please check the connection (interface between load sensor and displacement sensor).

6. Personal protection: There are no unrelated personnel in the testing area. A safety cover should be closed for tensile testing, and sufficient buffer space should be reserved for compression testing.