- Dynamic fatigue testing machine

- Friction and wear testing machine

- Fastener special testing machine

- Static mechanical property testing machine

- In-situ tensile testing machine

- Non-standard customized large and small mechanical equipment

- Metallographic sample preparation and analysis equipment

- hardmeter

- Solution of overall design and planning of laboratory

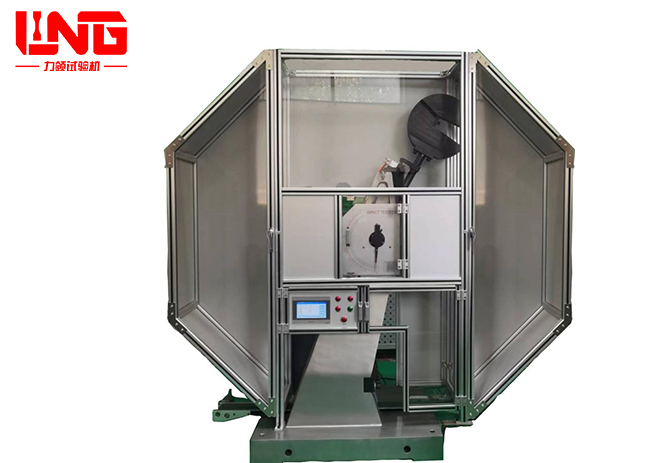

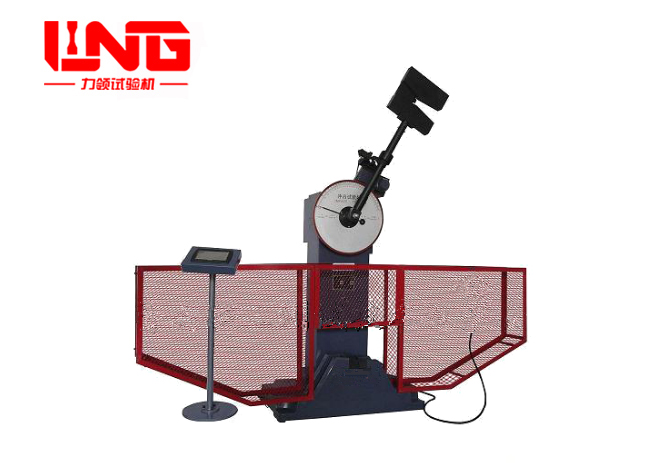

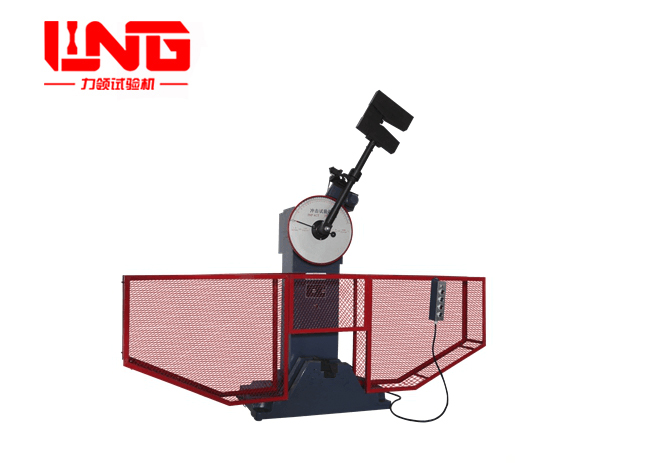

JBW-300C Microcomputer controlled pendulum impact testing machine

The metal pendulum impact testing machine is an instrument used to test the impact resistance of metal materials under dynamic loads

Introduction

This model can also be equipped with a fully automatic sample delivery system, which can greatly improve the efficiency of testing and reduce the labor intensity of testing personnel; An instrument based impact system can also be optionally selected, which can record and analyze various curves, data, and characteristic values of the entire impact process, and can output data and print test reports.

Parameters

|

Parameter |

Value |

|

Main Model |

JBW-300C |

|

Max. Impact Energy (J) |

300 |

|

Impact Velocity (m/s) |

5.24 |

|

Pendulum Pre-lift Angle (°) |

150 |

|

Angle Resolution (°) |

0.025 |

|

Distance from Swing Axis to Specimen (mm) |

750 |

|

Energy Loss on No-Load Strike |

≤ 0.4% |

|

Specimen Support |

|

|

- Span (mm) |

40±0.2 |

|

- End Radius (mm) |

1~1.5 |

|

- Support Surface Angle (°) |

11 ± 1 |

|

Impact Knife Edge |

|

|

- Radius (mm) |

2 or 8 |

|

- Angle (°) |

30 |

|

- Thickness (mm) |

16 |

|

Allowable Specimen Dimensions (mm) |

55×10×10; 55×10×7.5; 55×10×5; 55×10×2.5 |

|

Overall Dimensions (mm) |

2200×800×2050 |

|

Main Power Supply |

3-phase, 380V±10%, 50Hz, 1.5kW |

|

Main Unit Weight (kg) |

1150 |