- Dynamic fatigue testing machine

- Friction and wear testing machine

- Fastener special testing machine

- Static mechanical property testing machine

- In-situ tensile testing machine

- Non-standard customized large and small mechanical equipment

- Metallographic sample preparation and analysis equipment

- hardmeter

- Solution of overall design and planning of laboratory

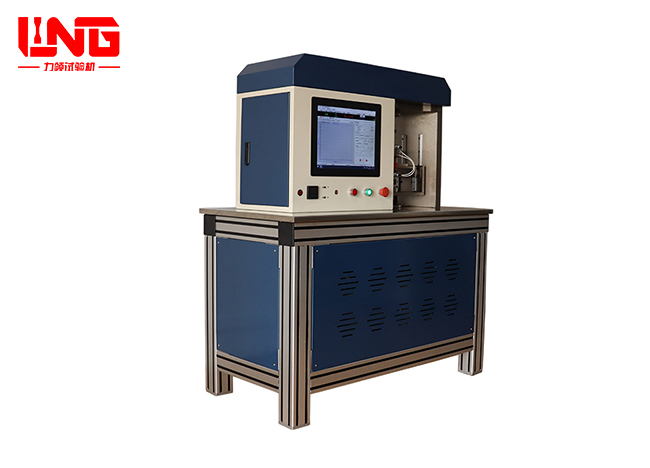

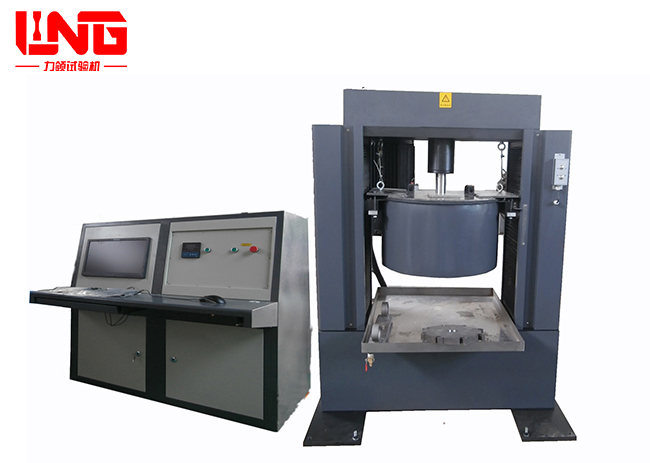

LZF-1 Rotating reciprocating friction and wear testing machine

The rotary reciprocating friction and wear testing machine has two motion forms, so it includes two testing modules, which are easy to replace and can meet more testing requirements.

Introduction

Rotating module: The equipment moves in a rotating manner, achieving various forms of friction contact and lubrication states, to simulate friction tests between different friction pairs. It has multiple friction pairs, such as pin disk friction pairs, end face friction pairs, ball disk friction pairs, etc. Capable of conducting friction simulation experiments on points, lines, and surfaces. Can be used to evaluate the friction and wear properties of lubricants, metals, coatings, coatings, rubber, ceramics, and other materials. Can meet the requirements of friction and wear testing for users in various industries such as petrochemicals, machinery, energy, metallurgy, aerospace, etc. for the development and testing of various high-end series of oil and grease products, as well as emerging material development and new process research.

Reciprocating module: The equipment moves in a reciprocating mode and is mainly used for testing the friction and wear performance of materials and surface coatings. Adopting industrial control computer control, the entire testing process is monitored and controlled in real time, with automatic constant loading of testing force and dynamic alternating loading (sine wave, triangular wave, square wave, trapezoidal wave), ensuring stable and reliable loading. It can simulate three forms of contact friction: point, line, and surface, and perform reciprocating motion to measure various parameters such as friction and wear under different loads, reciprocating frequencies, lubrication conditions, and temperatures.

Expandable corrosion resistance function, simulating experimental measurements in deep-sea environments.

Parameters

|

No. |

Technical Item |

Parameter Specification |

|

1 |

Reciprocating Frequency Range |

1 - 60 Hz, Stepless speed regulation, non-staged |

|

2 |

Rotational Speed Range |

1 ~ 3000 r/min, Stepless speed regulation |

|

3 |

Rotational Torque |

0 - 2.5 N·m |

|

4 |

Reciprocating Stroke Range |

60 mm, Accuracy: 0.01 mm |

|

5 |

Friction Force Measurement Range |

200 N, Measurement Accuracy: 2% |

|

6 |

Maximum Load |

500 N, Load Accuracy: 0.1 N |

|

7 |

Rotating Friction Pairs |

Small Pin-on-Disc Pair, Large Pin-on-Disc Pair, Small Thrust Washer Pair, Large Thrust Washer Pair, Ball-on-Disc Pair, Four-Ball Pair |

|

8 |

Reciprocating Friction Pairs |

Ball-on-Disc (Point Contact), Pin-on-Disc (Line Contact, Surface Contact) |

|

9 |

Timer Display and Control Range |

1 s ~ 99,999,999 s |

|

10 |

Lifting Height |

60 mm |

|

11 |

Test Medium |

Air, Oil, Water, Mud, Abrasive, etc. |

|

12 |

Temperature Heating Range |

Heating range can be increased to 600°C |