News (click to select category)

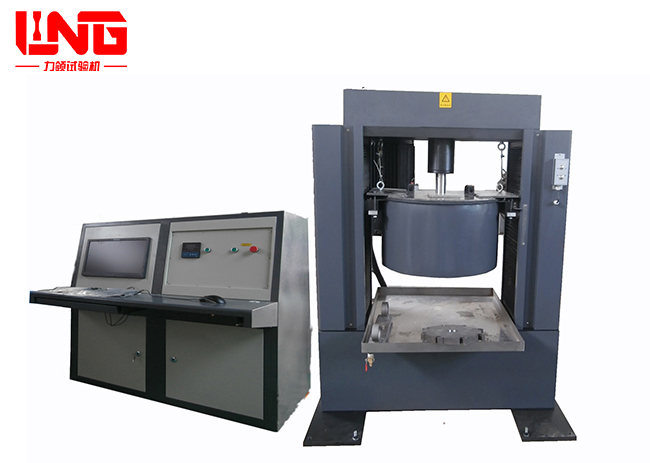

How to check if the tensile testing machine is working properly

Date:2024-05-11ID: 250Heat:

Daily appearance and basic function inspection (before each startup)

1. Appearance and environmental inspection

Body condition: Check for obvious physical damage, rust, or oil stains on the host and accessories.

Power and grounding: Confirm that the power cord is firmly connected and the grounding wire must be reliably connected to prevent electric shock and data interference.

Surrounding environment: There is no strong vibration or electromagnetic interference around the equipment, and the ambient temperature/humidity meets the equipment requirements (usually room temperature 10-35 ℃, humidity ≤ 80%).

2. Basic mechanical function inspection

Beam operation: Under no-load conditions, the control software allows the beam to run up and down at different speeds. Listen for any abnormal noise (such as friction or impact) and observe if the operation is smooth and without any jamming.

Emergency stop button: Press the emergency stop button to check if the crossbeam can immediately stop moving. This is the most important safety check!

Limit switch: Manually trigger the upper and lower limit switches to check if the crossbeam can automatically stop.

3. Inspection of fixtures and accessories

Fixture installation: Confirm that the fixtures (wedge-shaped jaws, flat plates, etc.) have been correctly installed, tightened, and not loose.

Jaws and lining plate: Check for severe wear or damage to the jaw teeth and lining plate, which can cause the specimen to slip.

Other attachments: If using an extensometer, check if its connecting wires and measuring blade are intact, and if the gauge length is set correctly.

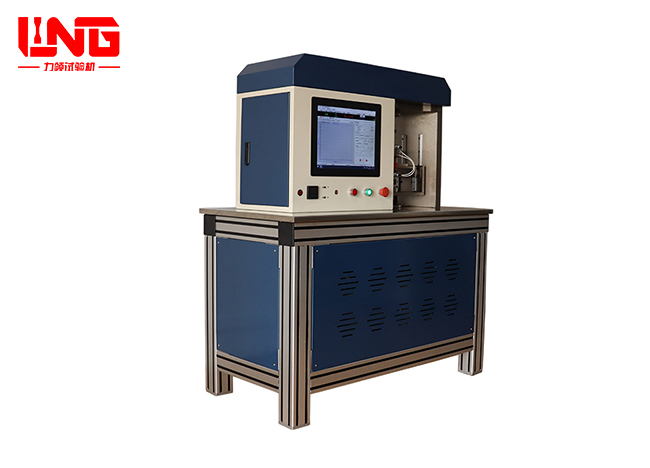

1. Appearance and environmental inspection

Body condition: Check for obvious physical damage, rust, or oil stains on the host and accessories.

Power and grounding: Confirm that the power cord is firmly connected and the grounding wire must be reliably connected to prevent electric shock and data interference.

Surrounding environment: There is no strong vibration or electromagnetic interference around the equipment, and the ambient temperature/humidity meets the equipment requirements (usually room temperature 10-35 ℃, humidity ≤ 80%).

2. Basic mechanical function inspection

Beam operation: Under no-load conditions, the control software allows the beam to run up and down at different speeds. Listen for any abnormal noise (such as friction or impact) and observe if the operation is smooth and without any jamming.

Emergency stop button: Press the emergency stop button to check if the crossbeam can immediately stop moving. This is the most important safety check!

Limit switch: Manually trigger the upper and lower limit switches to check if the crossbeam can automatically stop.

3. Inspection of fixtures and accessories

Fixture installation: Confirm that the fixtures (wedge-shaped jaws, flat plates, etc.) have been correctly installed, tightened, and not loose.

Jaws and lining plate: Check for severe wear or damage to the jaw teeth and lining plate, which can cause the specimen to slip.

Other attachments: If using an extensometer, check if its connecting wires and measuring blade are intact, and if the gauge length is set correctly.