Standard operation of fatigue testing machine

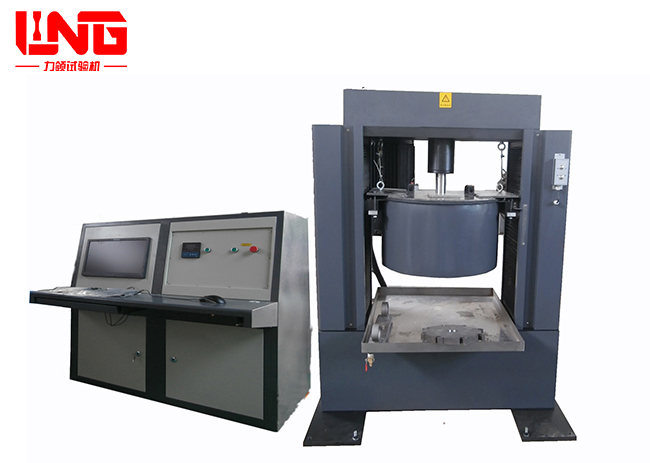

Fatigue testing machine is a common material testing equipment, mainly used to test the durability performance of materials or components under continuous repeated loading. The operating specifications of this equipment are crucial for the accuracy of test results and the stability of equipment operation. This article mainly introduces the standardized operation of fatigue testing machines to ensure the accuracy of testing and the safe and stable operation of equipment.

Equipment preparationBefore implementing testing, sufficient preparation work must be carried out on the equipment, including installation, calibration, and inspection 1. Installation: The installation of the fatigue testing machine should comply with national and enterprise standards. The equipment should be installed in a purification area to avoid pollution and vibration, and safety protection measures should be set up around the equipment.

2. Calibration: Equipment calibration is a key step in ensuring accurate and reliable test results. Before operating the equipment, it should be inspected and tested, including load, speed, displacement, and calibration of the measurement system, to ensure that it meets the testing requirements.

3. Inspection: Equipment inspection mainly includes checking the electrical and mechanical parts of the equipment to ensure that the equipment is intact and all components are working properly.

Operation steps

1. Install the sample onto the testing fixture to ensure its correctness and reliability.

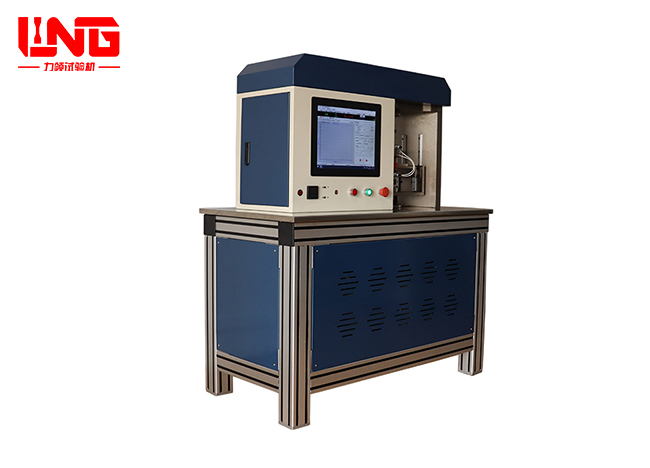

2. Turn on the power of the fatigue testing machine and activate the computer control system.

3. Set test parameters on the computer, including test temperature, frequency, amplitude, test frequency, maximum load, and minimum load, and conduct inspections.

4. Start the fatigue testing machine, and when the equipment reaches the set state, start testing and change the testing parameters based on the test data.

5. During the testing process, the condition of the specimen should be checked regularly, including the degree of deformation, surface cracks, etc., to prevent specimen failure or damage. 6. After the test is completed, the fatigue testing machine and computer system should be turned off, and the equipment should be cleaned and maintained.

Safety precautions

Attention should be paid to safety when operating the fatigue testing machine to prevent accidents from occurring.

1. When operating the equipment, one should accurately understand the equipment manual and follow the operating procedures.

Before starting the test, the safety protection measures of the equipment should be checked, including emergency stop switches, safety protection doors, etc., to ensure that they are working properly.

3. Regularly inspect and maintain equipment to ensure safe and stable operation.

During the testing process, the condition of the test piece should be checked regularly to prevent failure or damage, and to avoid damage to equipment or personnel.

By strictly following the operating procedures, the normal operation of the fatigue testing machine and the accuracy and reliability of the test conclusions can be ensured. In order to ensure the long-term stability of the equipment, it is also necessary to develop a maintenance plan for the equipment and conduct regular equipment inspections and calibrations.