The high-end electro-hydraulic servo fatigue testing machine independently developed by Jinan Liling successfully passed the acceptance test, helping China to take a new step in the autonomy of high-end equipment.

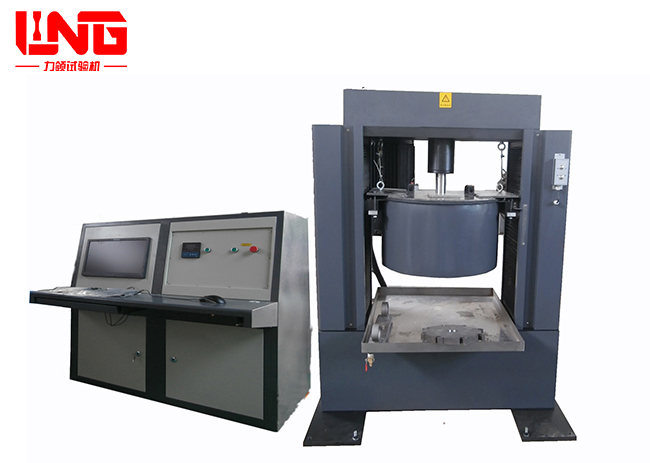

Recently, "LH series high-end electro-hydraulic servo fatigue testing machine" independently developed by Jinan Liling Testing Machine Manufacturing Co., Ltd. successfully passed the on-site technical review and performance assessment of the acceptance team composed of industry experts and key user representatives. The successful development and delivery of this equipment marks an important breakthrough in the field of reliability testing equipment for high-performance structural materials and core components in China, which provides a solid testing guarantee for the development of new quality productivity.

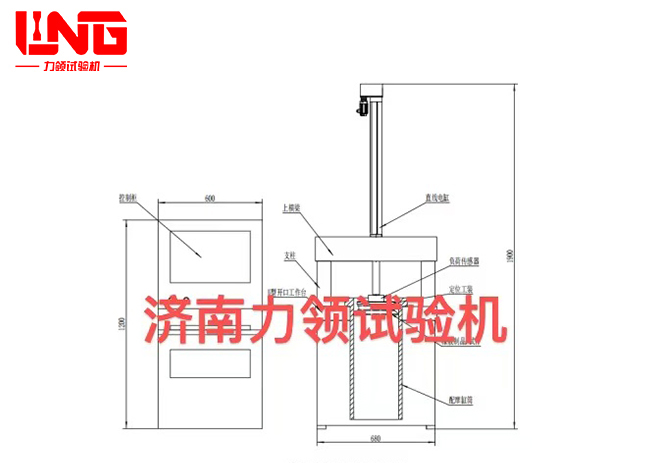

The testing machine that passed the acceptance this time is a high-performance testing platform with high precision, high dynamic response and large load. Its core technical indicators have reached the leading level in the industry, with the maximum static test force of ±200kN, dynamic test force of ±150kN and frequency range of 0.1-50Hz, which can accurately simulate various complex load conditions such as sine wave, triangular wave and trapezoidal wave. All-digital closed-loop servo control technology is adopted in the equipment. In the full range of 2%-100%, the static force value indication accuracy is as high as 1%, and the dynamic accuracy is better than 2%, which ensures the extremely accurate and reliable data acquisition.

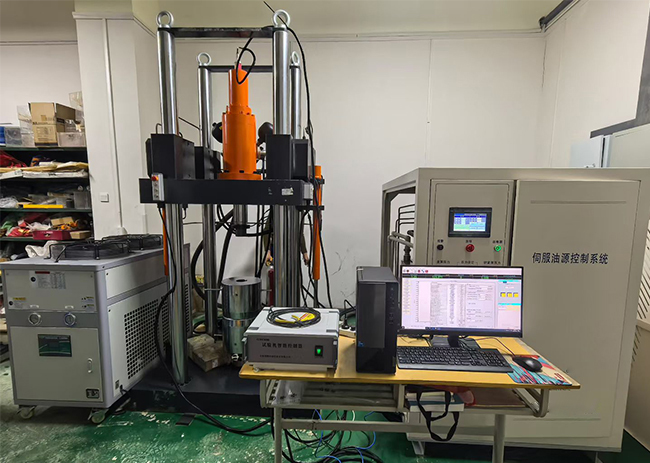

During the acceptance process, the expert group strictly examined the technical documents, design drawings and quality control records of the equipment, and witnessed the operation test of the equipment under various waveforms, different frequencies and ultimate loads. The operation stability, control accuracy, data consistency and convenience of man-machine interaction of the equipment fully meet and partially exceed the requirements of the technical agreement. Experts agree that the equipment has advanced design, excellent manufacturing and excellent performance, and its comprehensive technical indicators have reached the international advanced level, which can effectively solve the "stuck neck" problem faced by China in the reliability test of high-end equipment and has great popularization and application value.

The successful delivery and acceptance of Jinan Liling's high-end electro-hydraulic servo fatigue testing machine not only reflects the company's profound technical accumulation and innovation ability in the field of material testing equipment, but also is a positive response to the country's strategy of promoting high-end scientific instruments and equipment to be self-controllable. In the future, the company will continue to focus on cutting-edge testing technology, and provide stronger testing technical support and equipment support for independent innovation and safe and reliable operation of strategic industries such as aerospace, rail transit and new energy.